What is Feed Fortification?

Fortification is the addition of micronutrients viz. vitamins, minerals besides enzymes, prebiotics, probiotics etc. to feeds for poultry, cattle, and aquaculture etc. to improve the nutritional content. These nutrients may or may not have been originally present in the feed before processing or may have been lost in processing.

Micronutrient malnutrition contributes substantially to burden of disease and productions of eggs, milk and meat weight etc.

Correction of micronutrient deficiencies aim to ensure consumption of a diet that is adequate in every nutrient.

Feed fortification has dual advantage of being able to deliver nutrients, without changes in consumption patterns.

Why is Fortification Needed?

Fortification of animal feeds, including poultry, cattle, and aquaculture, with vitamins, minerals, toxin binders, enzymes, probiotics, and herbals is essential for optimal health and performance. These additives contribute to better growth rates, improved feed conversion, enhanced disease resistance, and overall productivity. For poultry, they improve egg production, bone health, and immunity, while enhancing digestion and reducing the need for antibiotics. For aquaculture, they support fish health, stress resistance, and digestion. For livestock, such fortification helps meet production demands viz. for milk, sustainably and economically. Fortification, therefore, is vital for producing healthier animals, including poultry, reducing production costs, and supporting environmental sustainability. Sources: FAO Livestock Nutrition, Journal of Animal and Feed Sciences, Journal of Poultry Science, Frontiers in

Veterinary Science; Journal of Livestock Science

Vitamins and minerals support growth, immune function, and metabolic processes, preventing deficiencies.

Toxin binders protect animals from harmful mycotoxins, ensuring feed safety.

Enzymes enhance nutrient absorption, improving feed efficiency and reducing environmental impact.

Probiotics promote gut health, boost immunity, and reduce the need for antibiotics

Herbals serve as natural growth promoters and antioxidants.

Our Feed Fortification Products

The Need

Nutrient Deficiencies in Natural Feed Ingredients: grains and oilseeds may lack essential vitamins and minerals, impacting growth and egg production. Journal of Food and Beverages, Feed Navigator

Improving Feed Efficiency & Productivity: enzymes improve digestion, leading to better feed conversion ratios (FCR), crucial for poultry meat and egg production. Feed Navigator

Combating Mycotoxins & Other Feed Contaminants: mycotoxins in feed reduce performance and lead to health issues. Toxin binders in feed help mitigate these risks. Feed Strategy

Reducing Antibiotic Use & Promoting Sustainable Farming: probiotics and herbal additives reduce reliance on antibiotics, improving gut health, critical for sustainable farming. Lark Engineering

Supporting Economic Growth: poultry is a significant contributor to rural economy. Better productivity helps farmers meet demand for meat and eggs, thus improving livelihoods.

Advantages

- Longer lasting premix, due to reduced reactivity of nutrients from environment exposure – from cutting-edge Microencapsulation Technology.

- Controlled release of nutrients in feed – from cutting-edge Microencapsulation Technology.

- Happy consumers due to assured nutrient delivery – from cutting-edge Microencapsulation Technology.

- Cost effective nutrient fortification – no investment in new equipment.

- Assured & consistent quality – COA available on request.

- Made from safe materials – SDS available on request.

- Brand loyalty & trusting consumers.

INTERMIX – ACIDO PH PLUS

Powder Feed & Gut Acidifier for Poultry Feed Supplementation

- ADVANTAGES:

- Reduce pathogenic (bacterial and fungal) load of water and gut

- Help in improve absorption and bio availability of nutrients

- Inhibits mold and improves intestinal health

- Acts against a wide range of fungi species like Aspergillus, Penicillium, Fusarium, etc.

- Have antimicrobial action, improve general health and performance

- Improve metabolism by altering gut micro flora

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG, 5 KG | Powder.

- For customized specifications and packing – contact us.

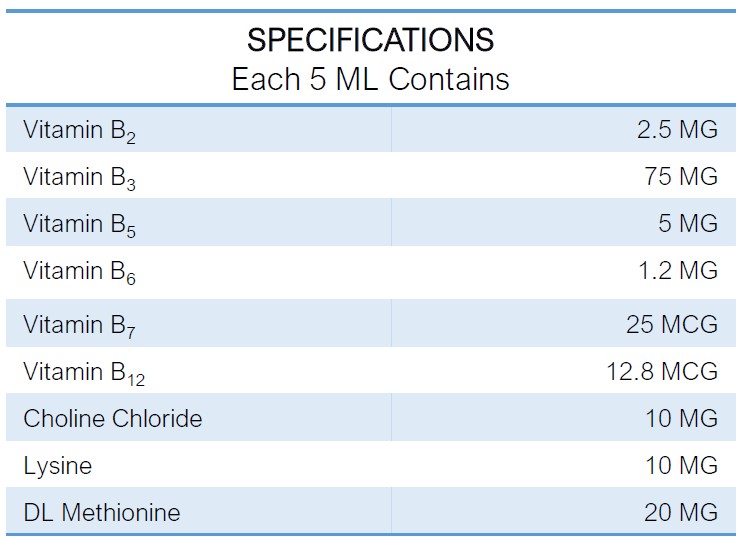

INTERMIX – BESOL WS

B Complex Concentrate with Amino Acids Essential Oils & Nutrients

- ADVANTAGES:

- Designed to meet B-Complex requirement through drinking water especially when feed uptake is reduced due to “stress”

- Restores normal metabolic functions and feed consumption in off-feed conditions

- Ensures normal growth, egg production, hatchability and gait by correcting Riboflavin deficiency

- Checks convulsive movements, head retraction & abnormal excitability caused by Pyridoxine deficiency

- Improves haemopoiesis growth and functioning of nerve cells by adequate B12 intake

- PACKING: 100 GM, 500 GM | Powder.

- For customized specifications and packing – contact us.

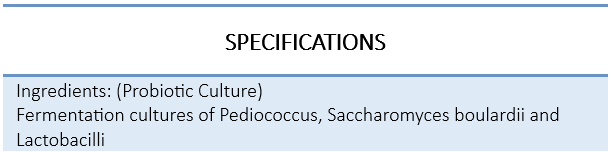

INTERMIX – BIOCOXICORP FEED MIXING

Poultry Feed Supplement for Biological Protection from Coccidiosis

- ADVANTAGES:

- Contains live Pediococcus Acidilactici, Saccharomyces Boulardii, and beneficial yeasts, friendly bacteria naturally found in animal and human intestines

- Enhances resistance of birds against Coccidiosis and elevates level of Anti-Eimeria antibodies

- Enhances humoral immunity and reduces number of oocysts shed by the bird infected with E. Tenella and E. Acervulina

- Survives the stomach acidic environment and works concurrently with antibiotics

- Helps restores healthy intestinal micro flora, suppresses food sensitivities and environmental changes resulting in stress

- PACKING: 1 KG | Powder.

- For customized specifications and packing – contact us.

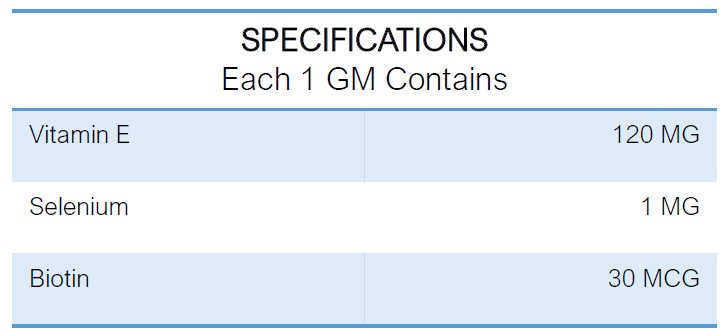

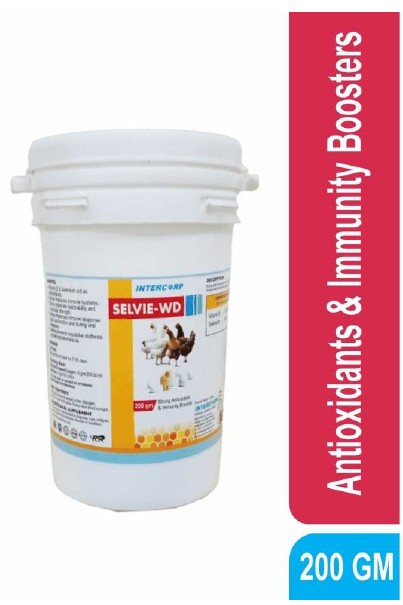

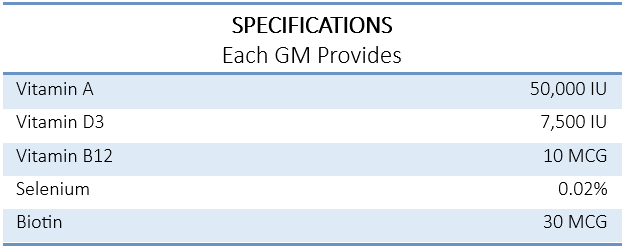

INTERMIX – BIOSELVIE WD

Strong Antioxidant & Immunity Booster

- ADVANTAGES:

- Improves defense mechanism

- Improves hatchability, growth, egg production and muscular strength

- Improves immune response during post vaccination and viral diseases

- Vitamin E and Selenium act as antioxidant and prevent tissue damage

- Biotin improves carbohydrate, lipid and protein metabolism

- Lasts longer – sealed under Nitrogen

- PACKING: 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

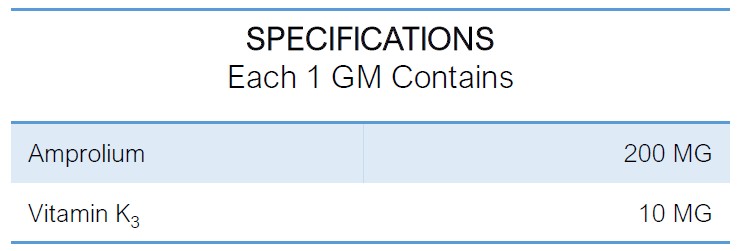

INTERMIX – COXICHECK WS

Vitamin K & Amprolium Premix

- ADVANTAGES:

- Highly effective against species of coccidia in chicken, turkeys, geese, ducks and emu

- Permits development of immunity when birds are exposed to coccidiosis

- Vitamin K checks blood droppings due to micro haemorrhages

- Effective & readily accepted when given through feed or drinking water

- Lasts longer – sealed under Nitrogen

- PACKING: 100 GM, 500 GM, 1 KG, 18 KG (18×1 KG) Drum | Powder.

- For customized specifications and packing – contact us.

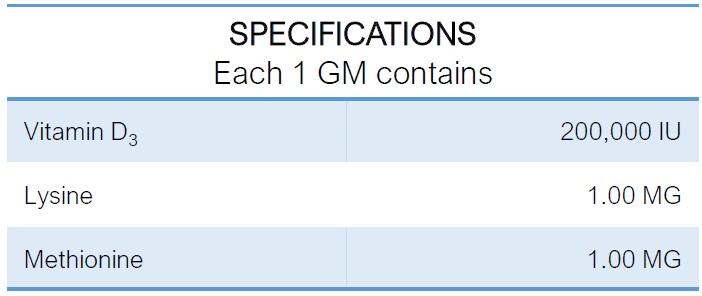

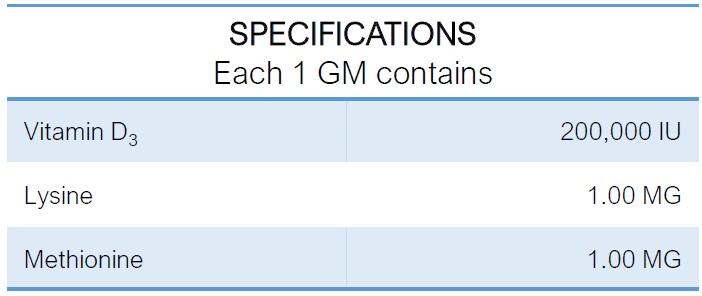

INTERMIX – D3 STRONG

Superior Vitamin D3 Premix for Poultry and Livestock Supplementation

- ADVANTAGES:

- D3 strong ensures better mobilization and absorption of Calcium & Phosphorus from the intestines

- Checks wing and leg lameness in poultry birds

- Improves egg production, shell quality & hatchability

- Enhances feed conversion & growth rate in broilers

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – D3

Vitamin D3 Premix

- ADVANTAGES:

- Ensures better mobilization and absorption of calcium & phosphorus from intestine

- Checks wing and leg lameness in poultry birds

- Improves egg production, shell quality & hatchability

- Enhances feed conversion & growth rate in broilers

- Livestock: Useful in metabolic disorders responsible for Calcium

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

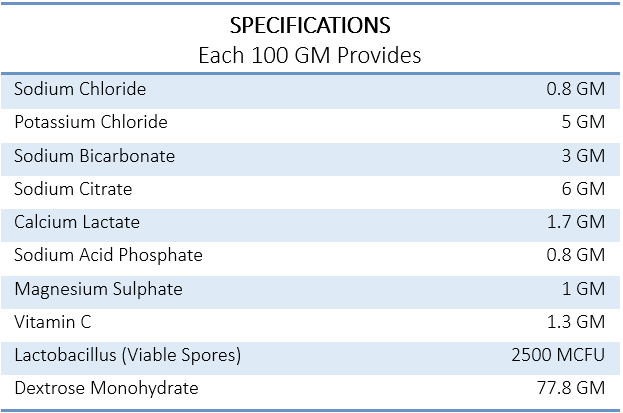

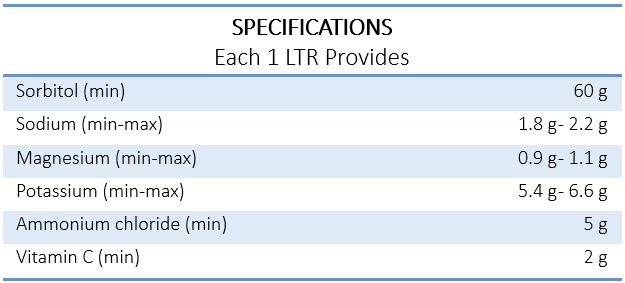

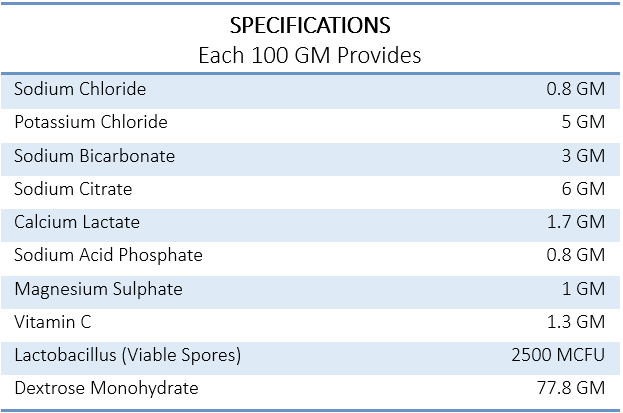

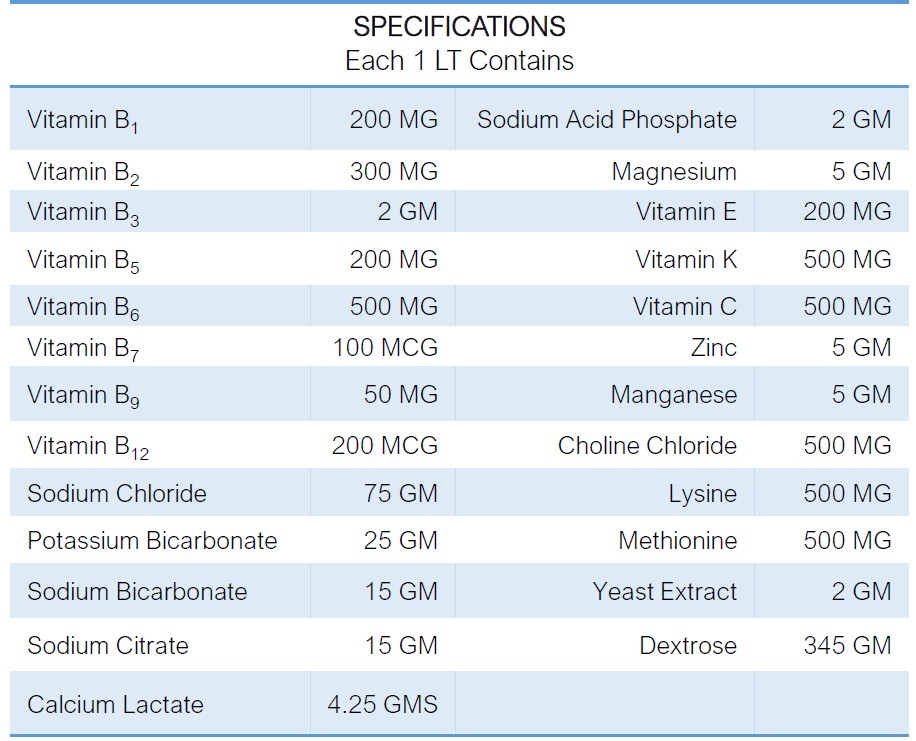

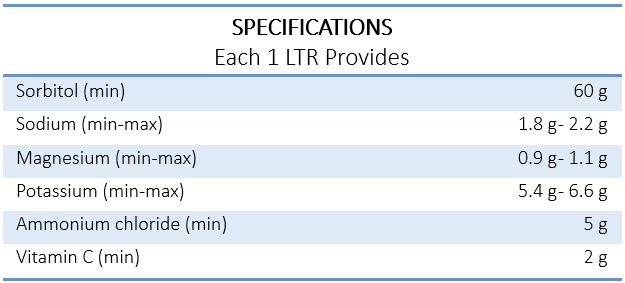

INTERMIX – ELECTROCORP WS (VET)

Perfect Combination for Electrolytic Balance

- ADVANTAGES:

- Immediately corrects electrolyte imbalance resulting from stressful conditions

- Restores mineral & fluid loss instantly in all species

- Promptly controls dehydration caused by diarrhea or High temperature transportation or vigorous exercise

- Convenient to administer through feed or drinking water

- PACKING: 500 GM, 1 KG, 5 KG, 25 KG (5 x 5 KG SUB PACKS) | Powder.

- For customized specifications and packing – contact us.

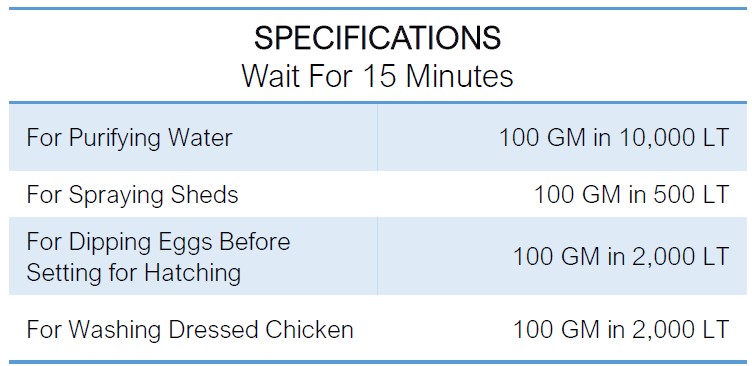

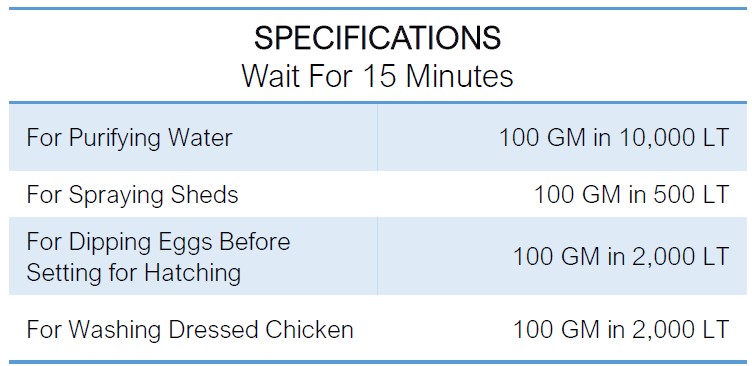

INTERMIX – ECOKILL

Water Sanitizer

- ADVANTAGES:

- Prevents bacteria, virus, and fungi

- Prevents re-contamination upto 72 hours

- Does not alter taste or pH of water

- Helps in faster sedimentation of physical impurities

- Lasts longer – sealed under Nitrogen

- PACKING: 100 GM, 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

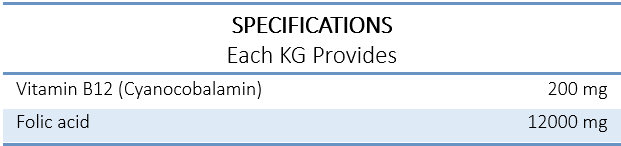

INTERMIX – FOLI-B STRONG

Vitamin B9 & Vitamin B12 Strong Feed Premix for Supplementation

- ADVANTAGES:

- Metabolism of nucleic acids and proteins

- Prevents nervous disorders and embryonic mortality

- Improves FCR (Feed Conversion Ratio)

- Enhances weight gain, egg size, feathering, and hatchability

- Improves feed intake and preventing anemic conditions

- Enhances growth, feathering, and egg production improving hatchability

- Prevents late embryonic mortality and leg deformities

- PACKING: 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

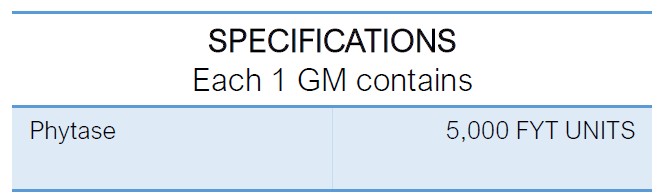

INTERMIX – FYTAZYME 5000

Phytase Premix

- ADVANTAGES:

- Makes feed easy to digest

- Ensure availability of mineral components for absorption & for further metabolism by breaking down phytic acids

- Increases energy value of feed

- Releases bound protein & phosphorus

- Improves metabolism & performance

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG Pouch, 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

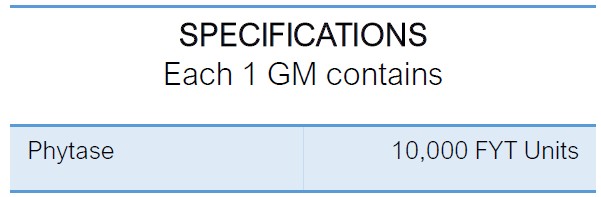

INTERMIX – FYTAZYME 10000

Phytase Premix

- ADVANTAGES:

- Makes feed easy to digest

- Ensure availability of mineral components for absorption & for further metabolism by breaking down phytic acids

- Increases energy value of feed

- Releases bound protein & phosphorus

- Improves metabolism & performance

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG Pouch, 25 KG (5×5 KG) Bag | Powder.

- For customized specifications and packing – contact us.

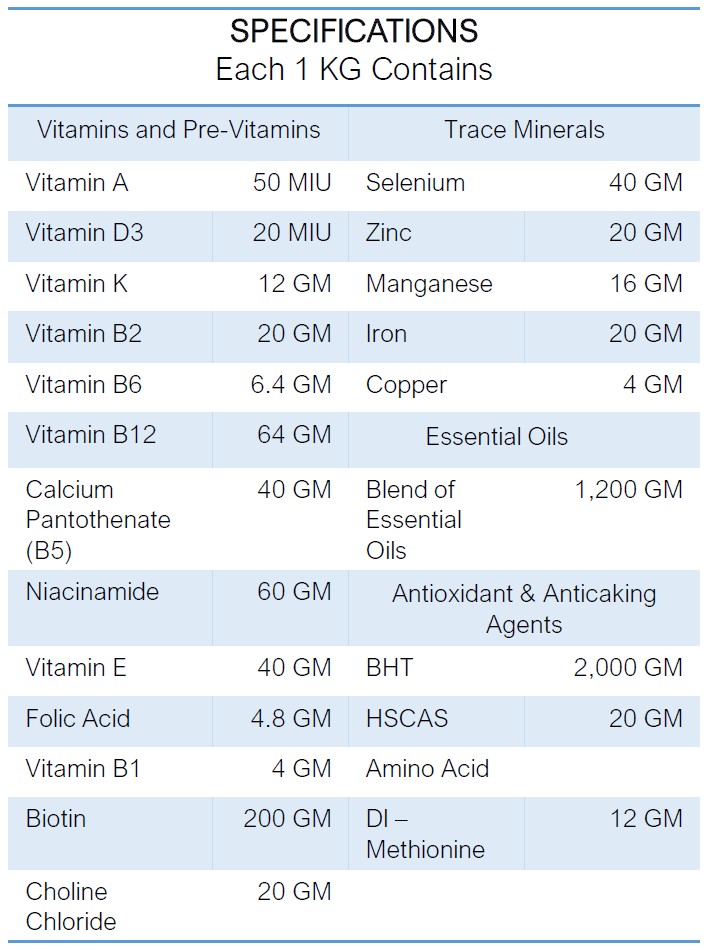

INTERMIX – GROWWITH 250

Blend of Vitamins with Super Supportive Supplements

- ADVANTAGES:

- Enhance Health, Growth, Egg Production in poultry

- Prevents treatment of Vitamin B group deficiency

- Appetite stimulant – improves enzyme secretion

- Activates immune response improves muscular strength

- Beneficial in respiratory issues in flocks

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG Pouch | Powder.

- For customized specifications and packing – contact us.

INTERMIX – IMOTECH STRONG

Superior Immunity Enhancer, Antistressor and Antioxidant Supplement

- ADVANTAGES:

- Enhances Natural and non-specific immunity

- Enhances phagocytosis and improves defense mechanism

- Improves vaccine titer and relieves stress

- Improves metabolism of carbohydrates, lipids and proteins

- Protects from production loss and improves muscular strength

- Acts as antioxidant and reduces cell membrane damage

- Improves hatchability in Breeders and Body weight in Broilers

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG, 25 KG Pouch | Powder.

- For customized specifications and packing – contact us.

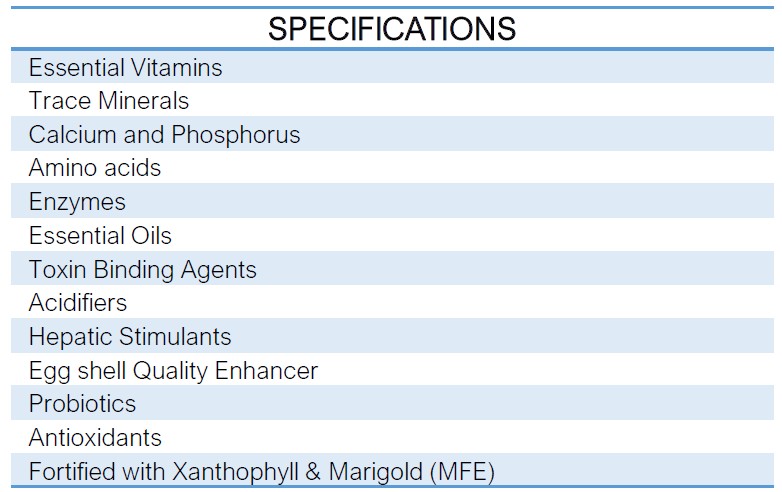

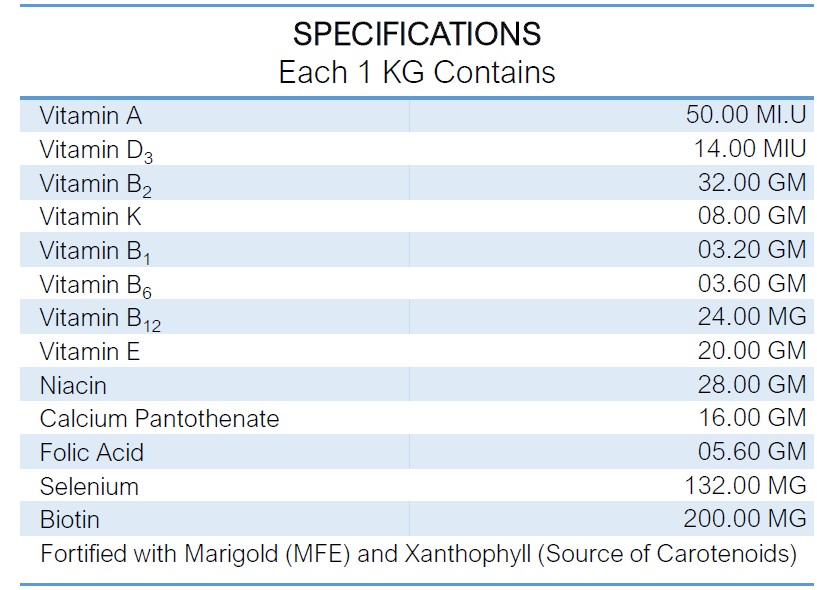

INTERMIX – LAYERGUARD

Balanced Nutrition Fortified with Xanthophyll & Marigold

- ADVANTAGES:

- Ensures balanced nutrition in diet

- Prevents fungus, virus, and bacteria

- Enhance appetite stimulation

- Improve carbohydrate, lipid and protein metabolism

- Improves hatchability and muscular strength

- Cost effective and convenient in use

- Lasts longer – sealed under Nitrogen

- PACKING: 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

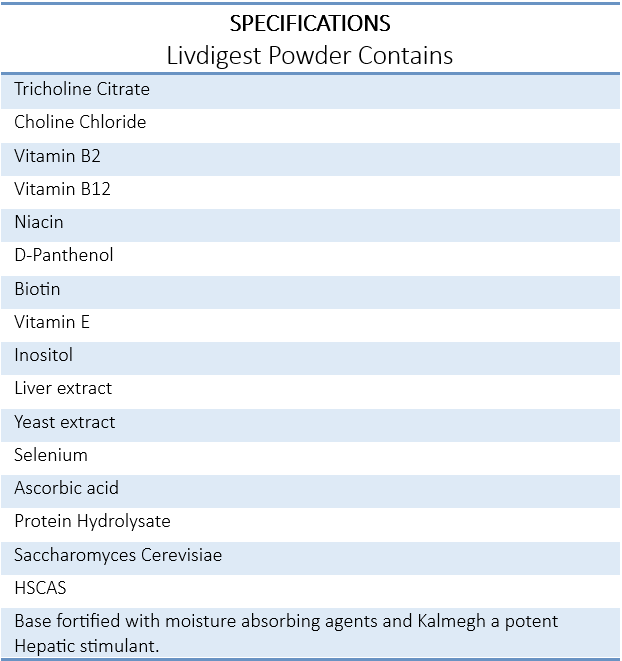

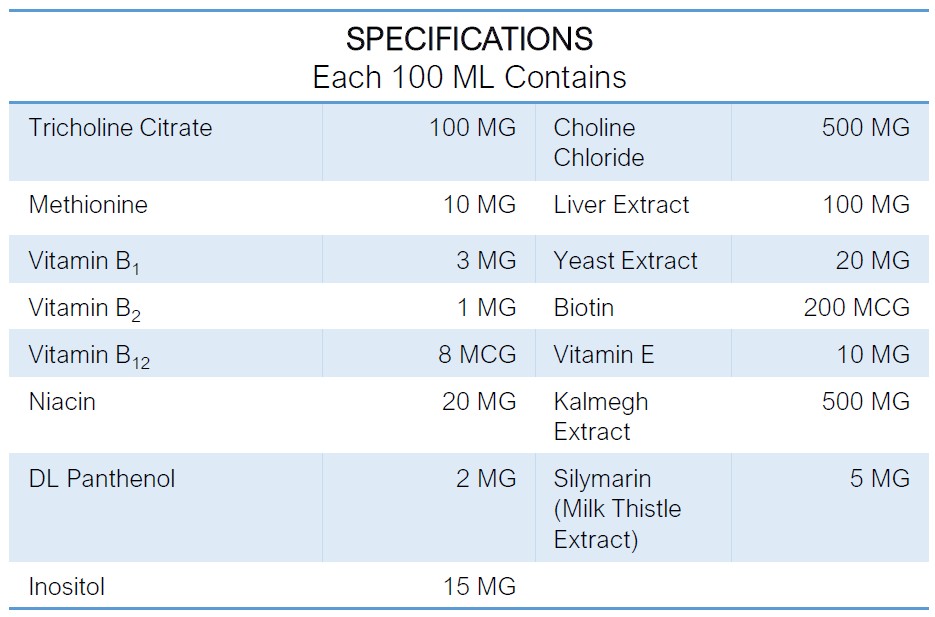

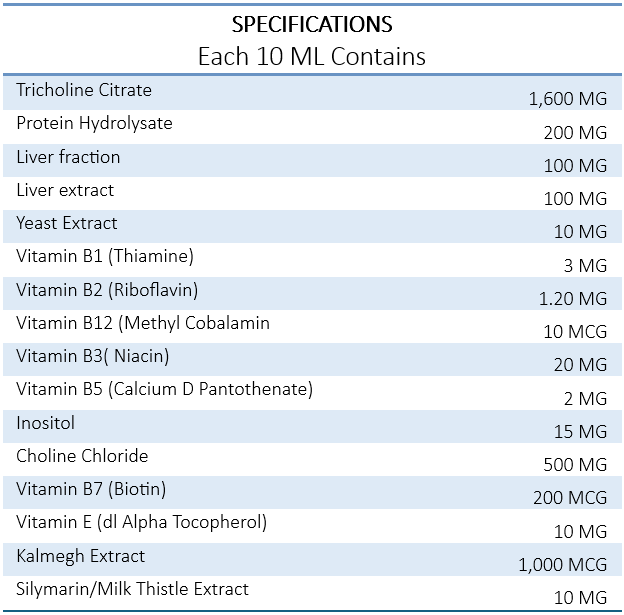

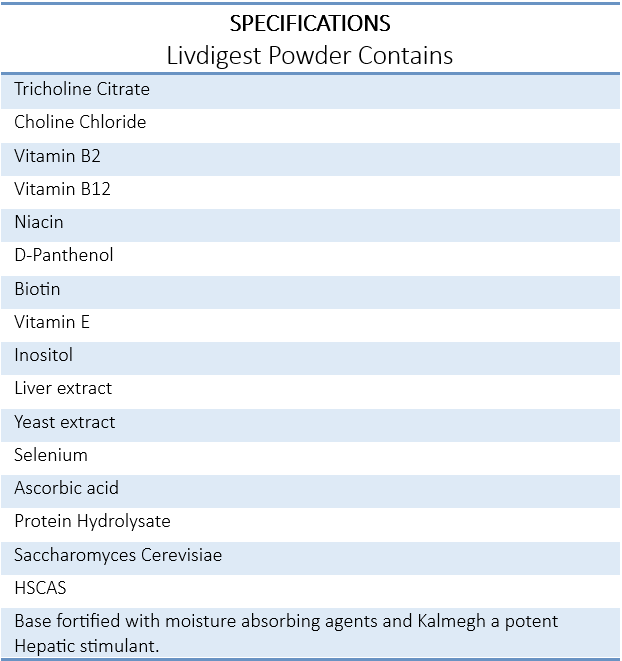

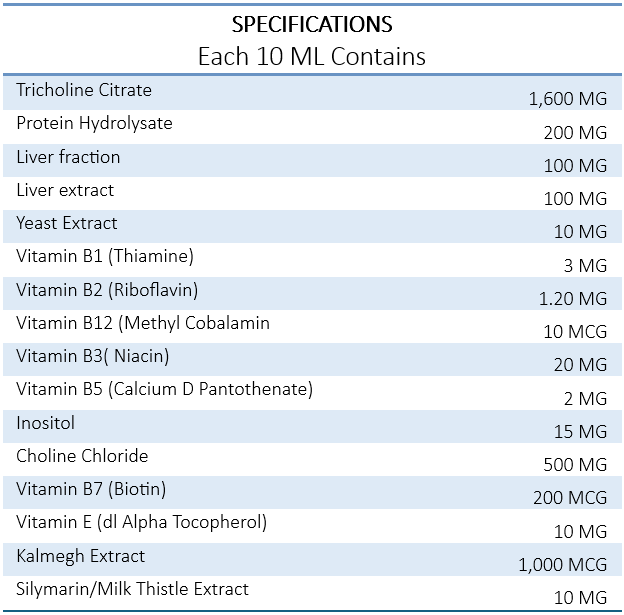

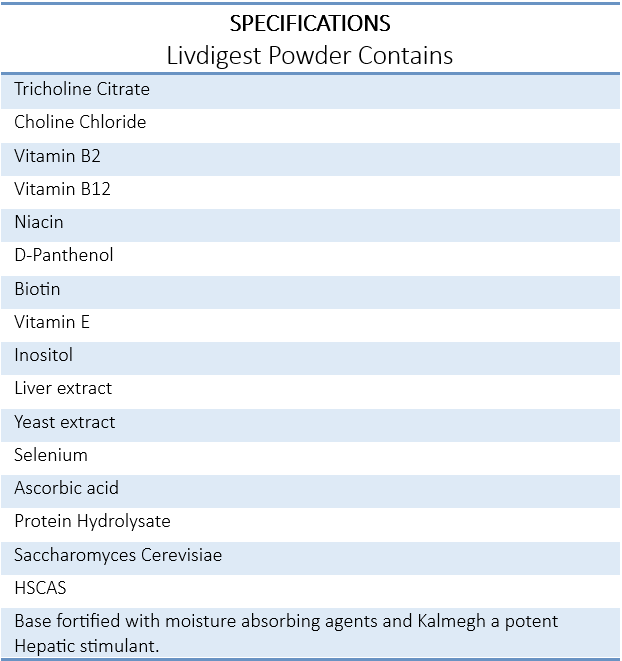

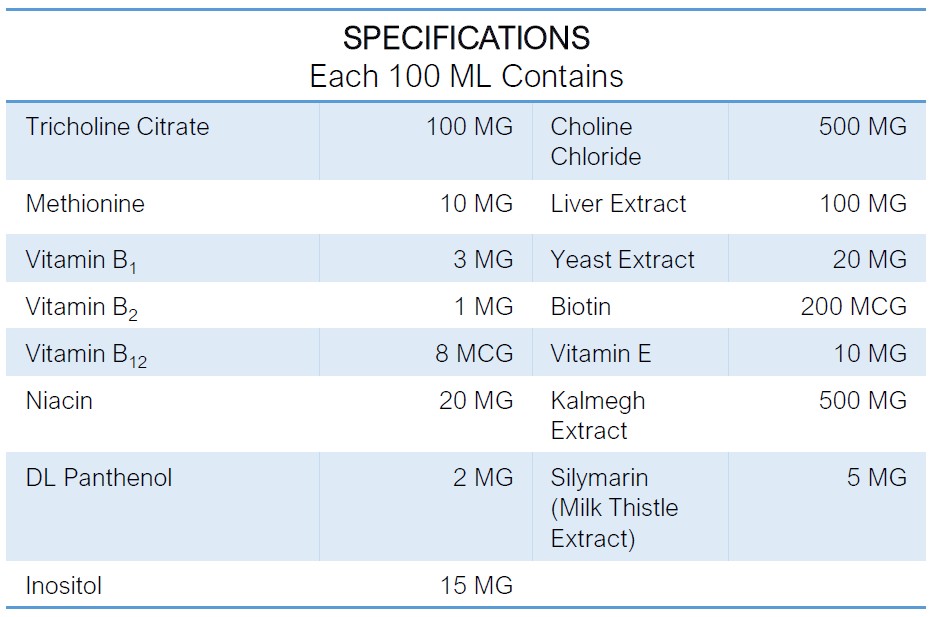

INTERMIX – LIVDIGEST

Water Miscible Liver Tonic for Protection & Performance Supplementation

- ADVANTAGES:

- Perfect combination of metabolic stimulants, antioxidants, vitamins, detoxifiers, and highly effective hepatic stimulants.

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function

- Improves metabolic processes

- Combats stress and improves FCR

- Useful in hepatic damage due to fungal and other hepatotoxins

- Mobilizes fat from liver and protects liver from fatty changes & cirrhosis

- Improves immunity, Egg production and body weight

- Supports nephrotic tissue functions

- PACKING: 1 KG Pouch, 25 KG (5x5KG) | Powder.

- For customized specifications and packing – contact us.

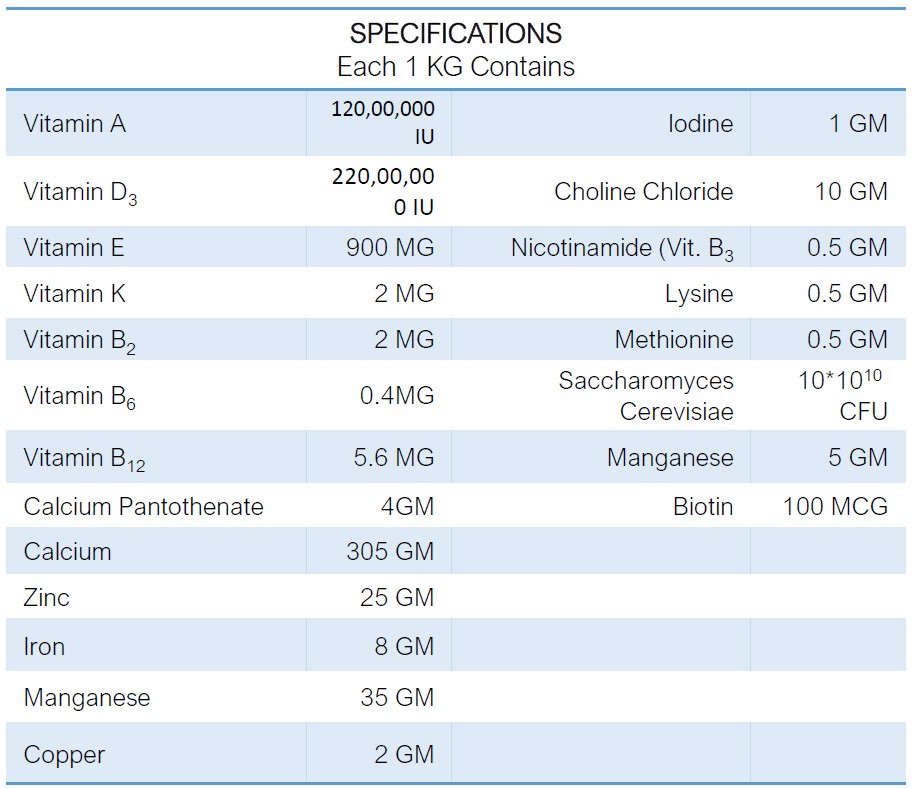

INTERMIX – MULTIMIX FORTE

Multi-Vitamin & Enzymes Mixture with Iron

- ADVANTAGES:

- Enhances health, growth, mass, weight, production, and prevents deficiency in animals

- Improves metabolism and capacity of feed intake

- Well accepted for poultry and livestock ration

- Can be used in manufacturing of feed supplements for various species

- Lasts longer – sealed under Nitrogen

- PACKING: 30 KG DRUM | Powder.

- For customized specifications and packing – contact us.

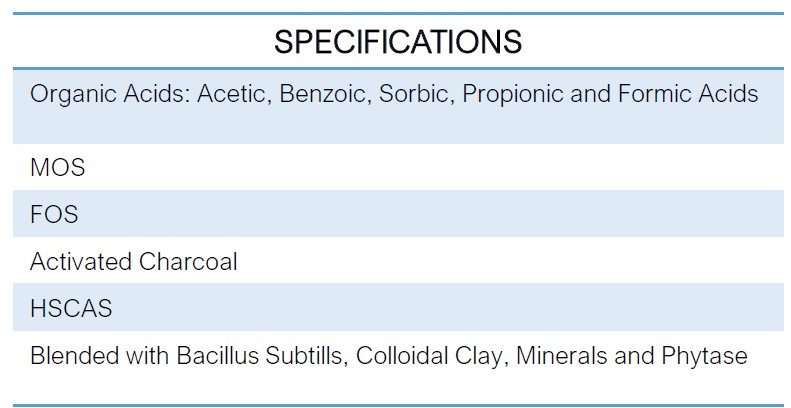

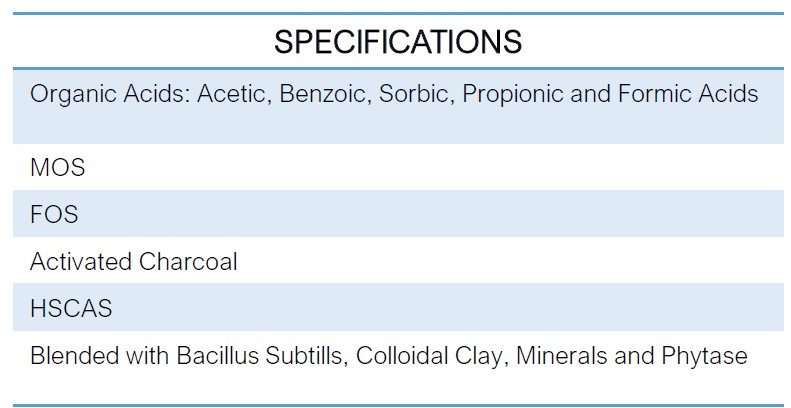

INTERMIX – MYTIBIND EXPO (IMPROVED)

Broad Spectrum Toxin Binder

- ADVANTAGES:

- Organic acids – act as mold inhibitor and prevent formation of mycotoxins

- Ability to blind T-2 Toxins and helps in absorption of nutrients

- Activated Charcoal – inactive chemical toxins not absorbed by HSCAS and MOS

- Base prevents growth of pathogens, mobilizes nutrients for better absorption

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Pouch, 5 KG, 25 KG (5x5KG), 25 KG (no sub-pack) Bag | Powder.

- For customized specifications and packing – contact us.

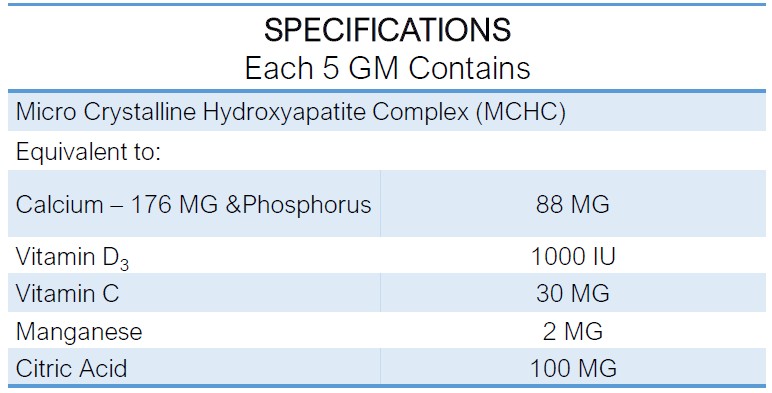

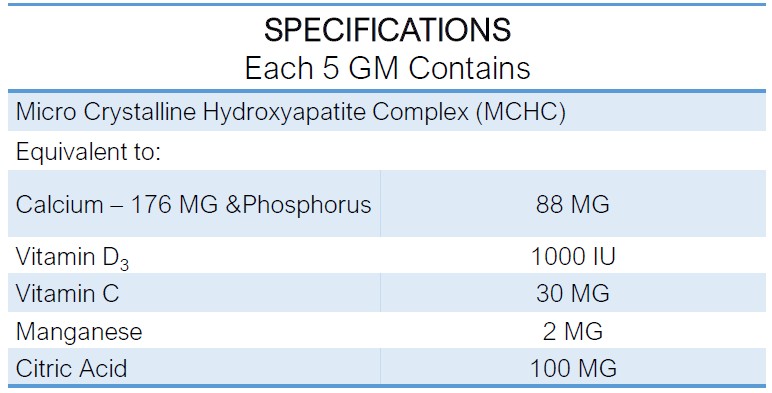

INTERMIX – ORTHOCAP

Calcium & Phosphorus Premix for High Skeletal Strength

- ADVANTAGES:

- Super strong doubles strength formula

- High bioavailability of natural Calcium and Phosphorous from MCHC

- Helps in faster growth with stronger bones

- Perfect source of organic minerals and collagen

- Vitamin D3 and C enhances absorption & assimilation of Calcium and Phosphorous

- Manganese improves metabolism of carbohydrate, fat and protein

- Citric acid (acidifier) maintains intestinal pH and improves absorption of Calcium and Phosphorous

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Feed mixing: 5-10 GM/KG of feed

- Pond water: 5-10 KG/Acre of pond water

- Or as advised by nutritionist/veterinarian

- PACKING: 1 KG Pouch, 5 KG Pouch, 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

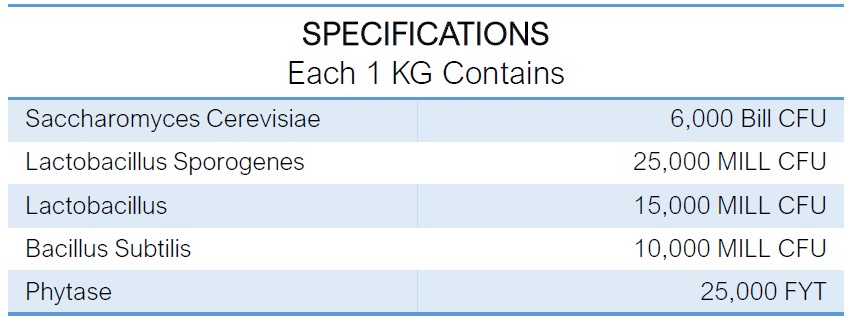

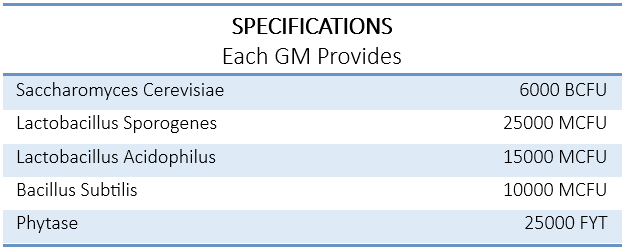

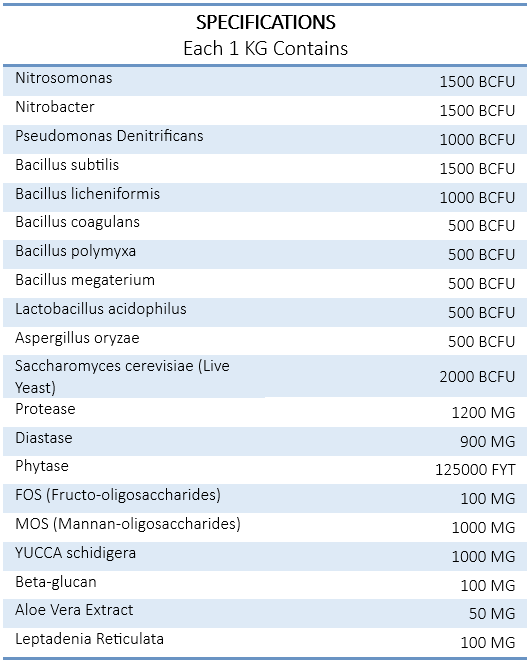

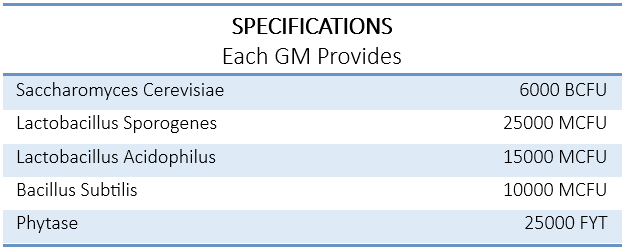

INTERMIX – PROBEE (FEED MIXING)

Probiotics & Enzyme Premix

- ADVANTAGES:

- Lactobacillus competes with harmful coliforms & pathogenic microbes for the site of adherence on the intestinal surface & result in competitive exclusion

- Reduction in early chick mortality. Better weight & egg production

- Reduces stress during vaccination & debeaking

- Provides enzymes for phosphorus, fat & protein digestion

- Source of vitamin B-complex. Improves feed conversion

- Immunostimulant action by activation of antibodies by bacillus subtilis

- Lasts longer – sealed under Nitrogen

- PACKING: 25 KG (No subpack) Drum | Powder.

- For customized specifications and packing – contact us.

INTERMIX – PROBEE WATER MISCIBLE

Probiotics & Enzyme Premix

- ADVANTAGES:

- Lactobacillus competes with harmful coliforms and pathogenic microbes on the intestinal surface, resulting in competitive exclusion

- Helps in production of lactic acid that reduces gut pH, lowering pathogen levels and reducing E. coli, Salmonella, and Staphylococcus count

- Reduces early chick mortality; promotes better weight gain and egg production

- Reduces stress during vaccination and de-beaking

- Provides enzymes for Phosphorus, Fat, and Protein digestion

- Enhances metabolism of Carbohydrates

- Yeast ferments Carbohydrates and inactivates toxins

- Acts as a source of Vitamin B-Complex and improves feed conversion

- PACKING: 100 GM, 1 KG, 5 KG, 25 KG | Powder.

- For customized specifications and packing – contact us.

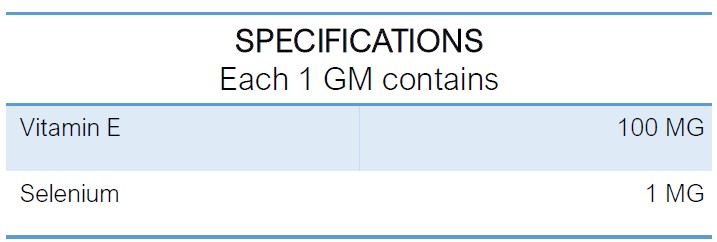

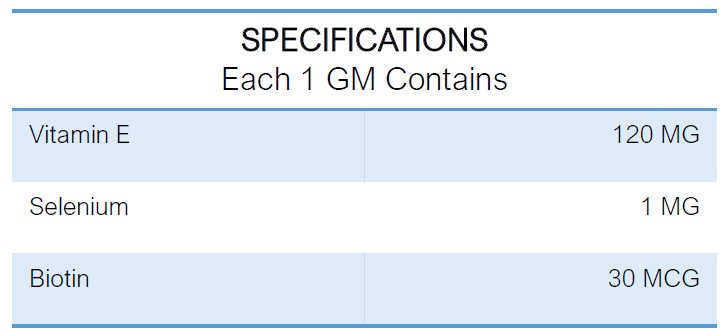

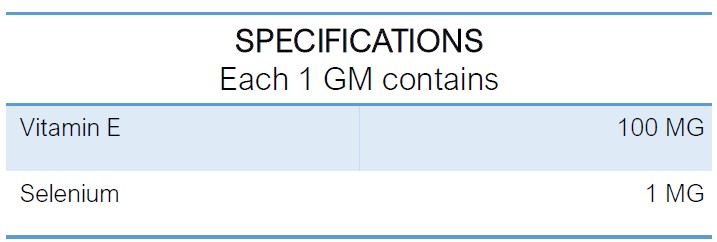

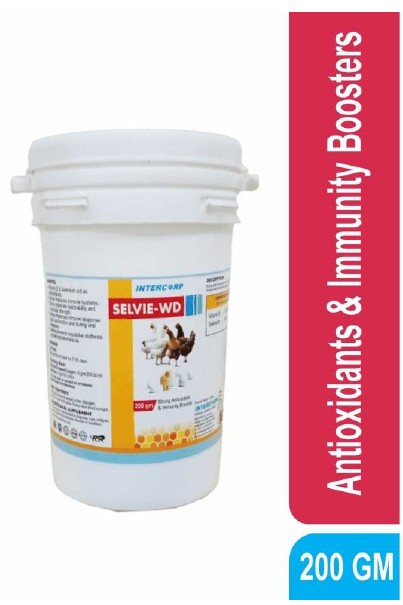

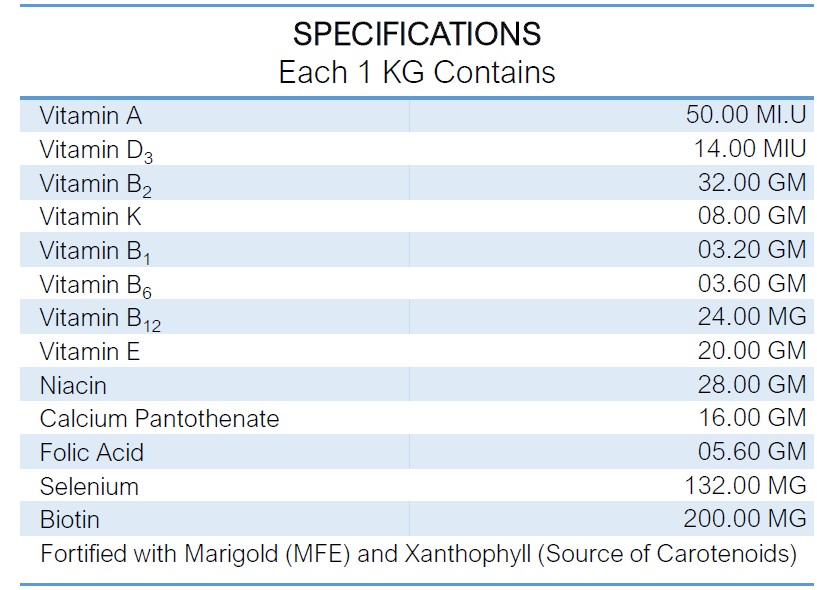

INTERMIX – SELVIE WD

Antioxidant & Immunity Booster

- ADVANTAGES:

- Vitamin E & Selenium act as antioxidants

- Improves immune systems

- Improves hatchability and muscular strength

- Improves immune response post vaccination and during viral diseases

- Prevents exudative diathesis and encephalomalacia

- Lasts longer – sealed under Nitrogen

- PACKING: 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

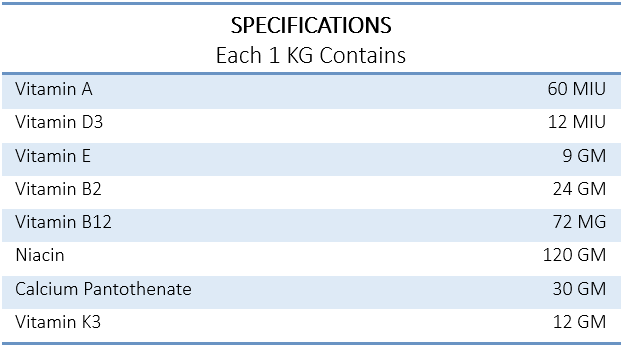

INTERMIX – SUPERMIX NZ

Vitamin Premix for Layers

- ADVANTAGES:

- For Vitamin B group deficiency

- Enhances health, growth, mass weight and egg production in poultry

- Provides Vitamin D necessary for absorption of phosphates

- Carotenoids: improve egg production and egg yolk colour

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG Pouch, 25 KG (5×5 KG) Bag, 25 KG (5X5 KG) Drum | Powder.

- For customized specifications and packing – contact us.

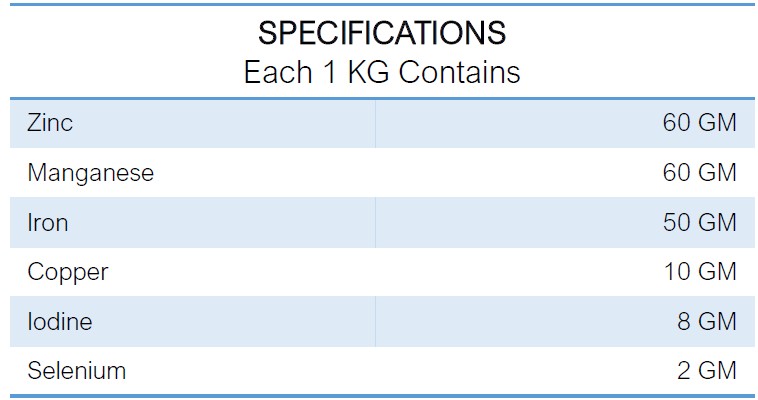

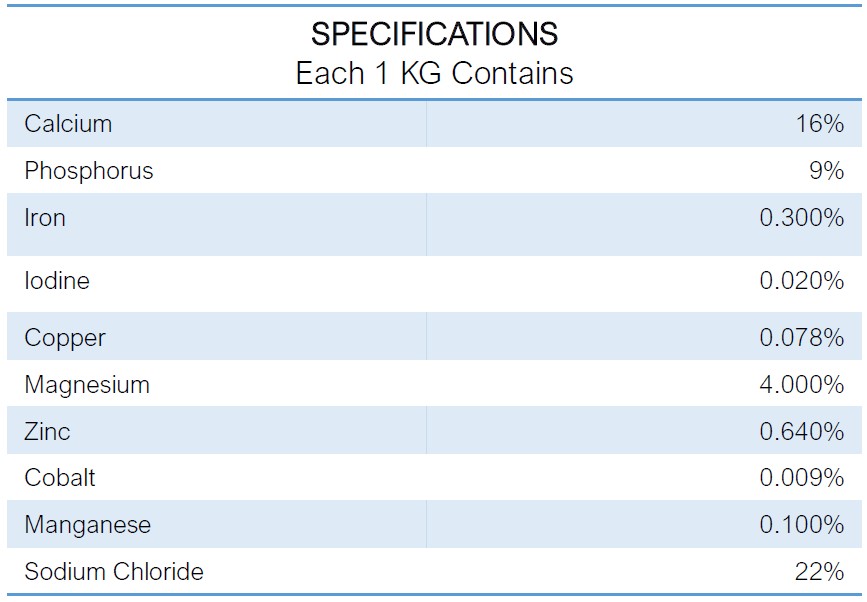

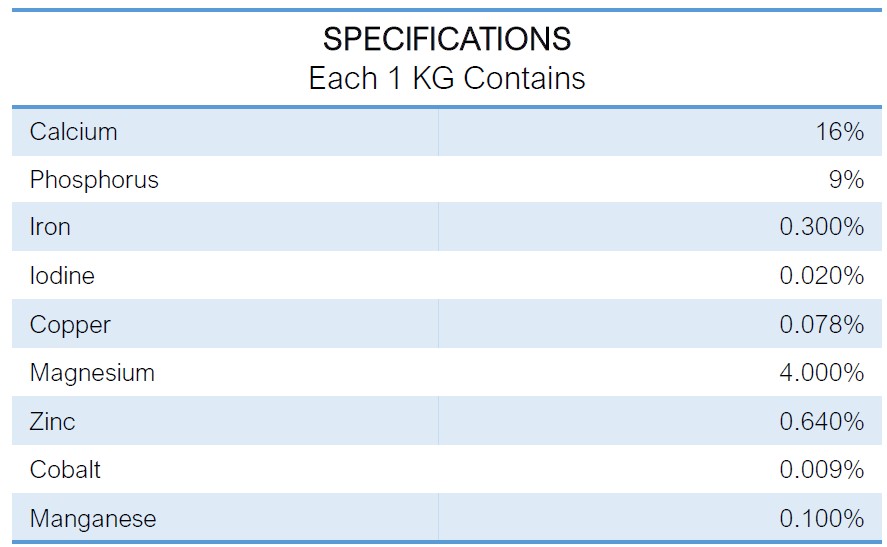

INTERMIX – TMCORP

Trace Mineral Mixture for Healthy Growth

- ADVANTAGES:

- Trace Minerals play a vital role in metabolic, enzymatic and biochemical reactions. Regular use of trace mineral improves growth rate, FCR and hatchability and protects the fish from deficiency diseases and metabolic disorders

- A perfect blend of essential micronutrients with base material enriched with calcium supplement for use in aquaculture.

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- 2-3 GM/KG of feed

- Or as advised by nutritionist/veterinarian

- PACKING: 5 KG, 25 KG (No subpack) Bag | Powder.

- For customized specifications and packing – contact us.

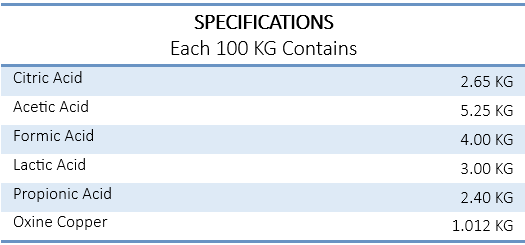

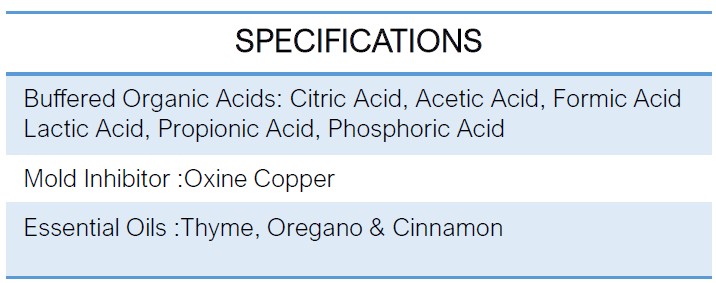

INTERMIX – ACIDO PH PLUS

Feed & Gut Acidifier

- ADVANTAGES:

- Buffered Organic Acids

- Reduce pathogenic (bacterial and fungal) load of water and gut

- Help in improve absorption and bio availability of nutrients

- Oxine Copper

- Inhibits mold and improves intestinal health

- Acts against a wide range of fungi species like aspergillus Penicillium, Fusarium

- Natural Essential Oils

- Has antimicrobial action, improves general health and performance

- Improves metabolism by altering gut micro flora

- Lasts longer – sealed under Nitrogen

- Buffered Organic Acids

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

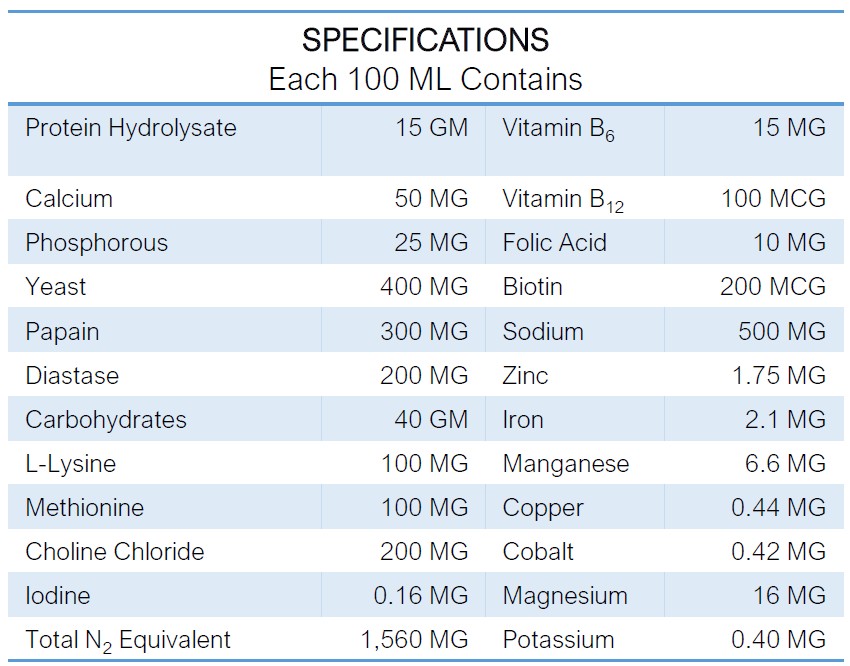

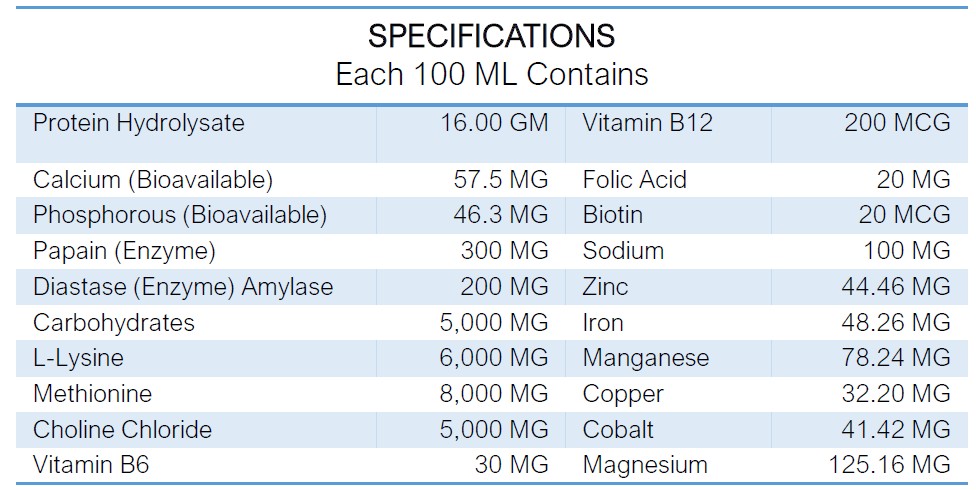

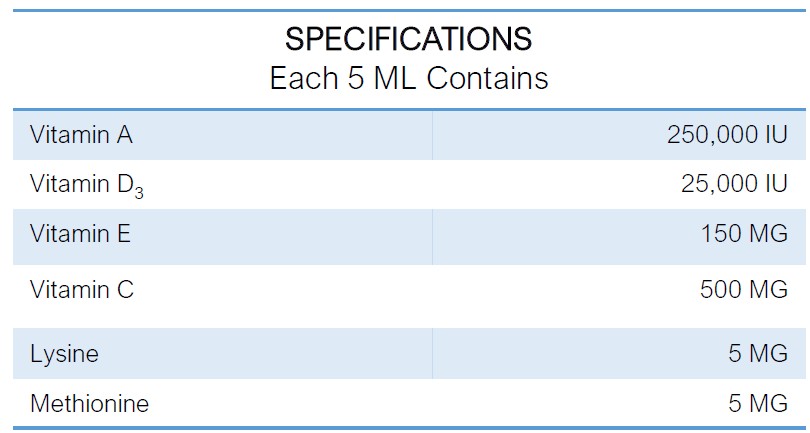

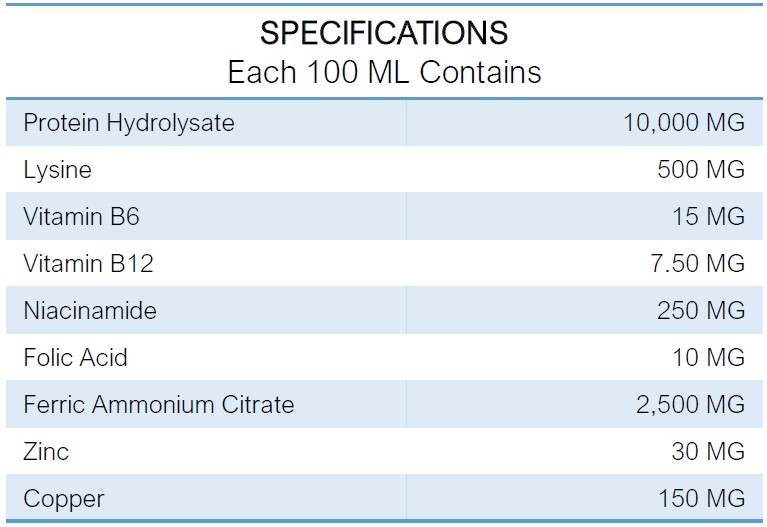

INTERMIX – AMINOBLEND

Blend of Essential Amino Acids, Enzymes, Vitamins & Minerals

- ADVANTAGES:

- For health, growth, mass, weight and egg production

- Diastase breaks starch into simple sugars and provides energy

- Lysine and Methionine improve calcium absorption, egg formation and build breast muscle in boilers

- Trace minerals improve metabolic, enzymatic and biochemical reactions

- Vitamin B6& Vitamin B12 prevent fatigue, improve digestion & neurological symptoms

- Calcium & Phosphorous prevent leg weakness and improve egg-shell quality

- Biotin improves metabolism of carbohydrates, protein and fat

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – AMINOBLEND (DS)

Blend of Essential Amino Acids, Enzymes, Vitamins & Minerals

- ADVANTAGES:

- Protein Hydrolysate – a potent source of essential amino acids

- Diastase breaks starch into simple sugars and provides energy

- Vitamin B6& Vitamin B12 prevent fatigue, improve digestion & neurological symptoms

- Calcium & Phosphorous prevent leg weakness and improve egg-shell quality

- Biotin improves metabolism of carbohydrates, protein and fat

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

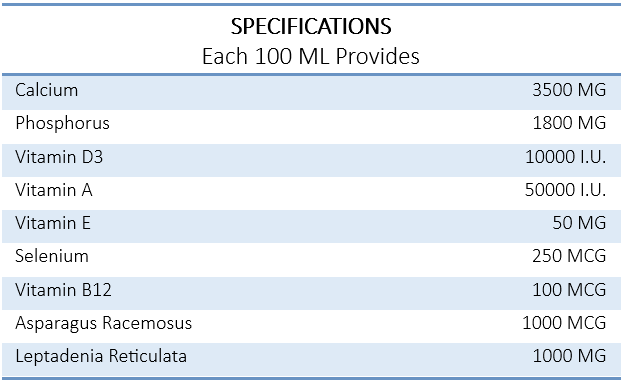

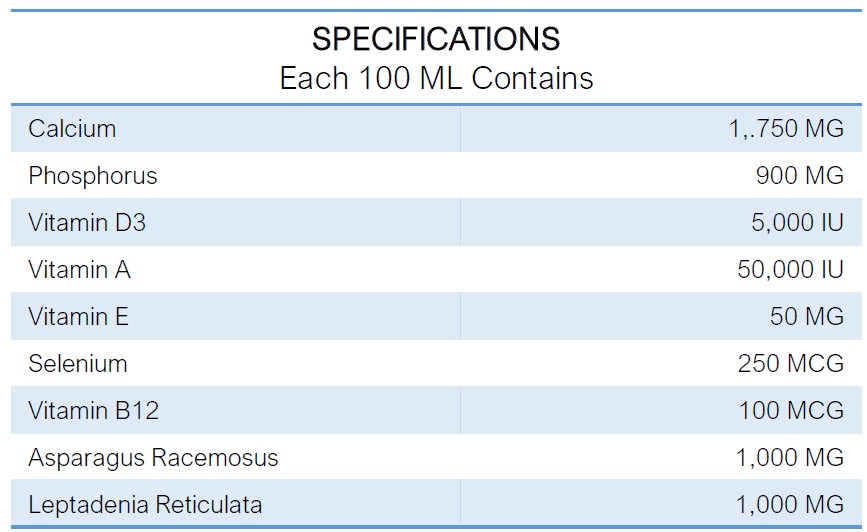

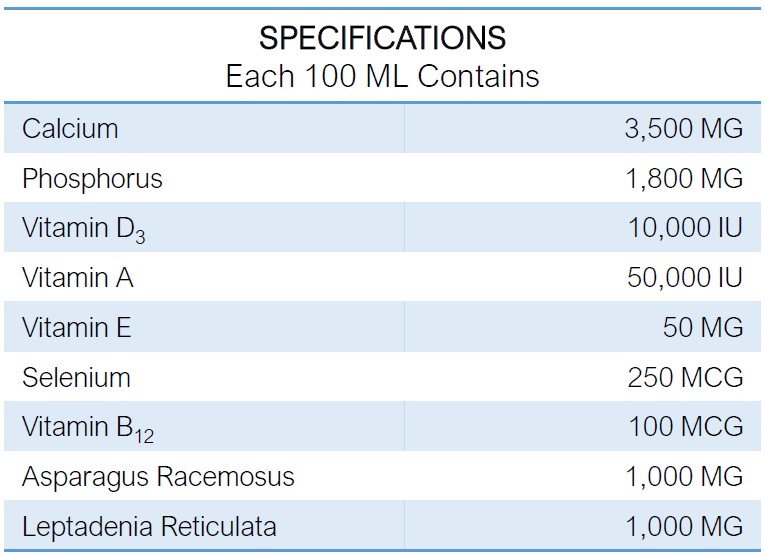

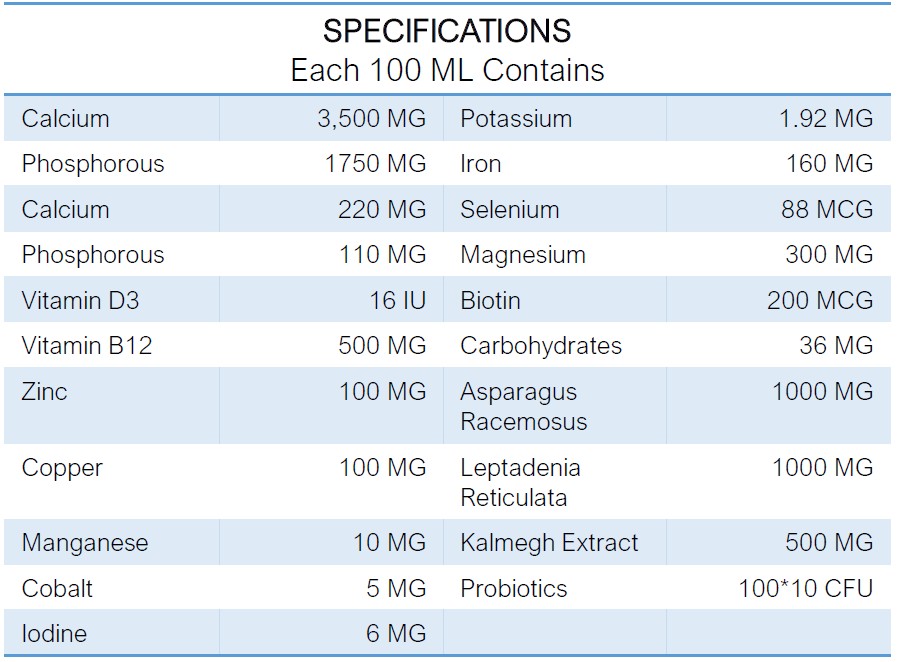

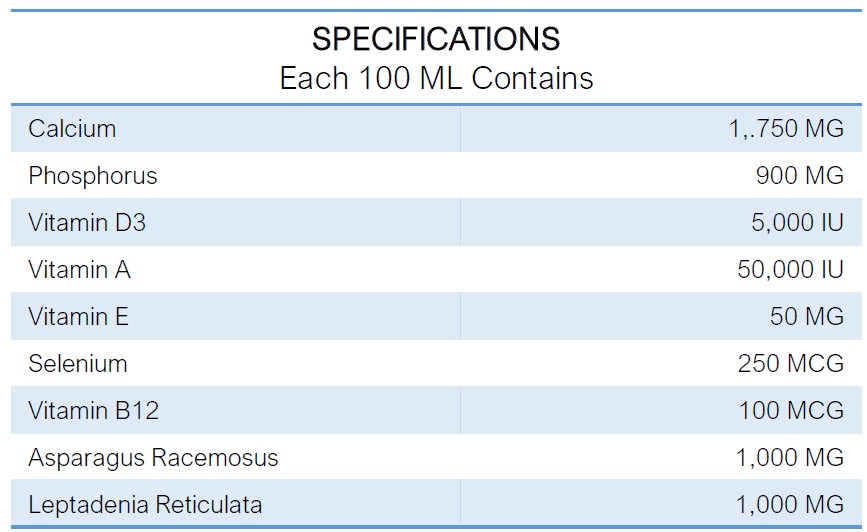

INTERMIX – CALCIVITE-H-DS

Superior Calcium Tonic with Synergistic Nutrients Supplement

- ADVANTAGES:

- Prevents breakage of eggs

- Prevents leg weakness, ensures faster growth and stronger bones

- Vitamin D3 is necessary for absorption & assimilation of Calcium & Phosphorous

- Vitamin A, E & Selenium improve neurological functions

- Asparagus and Leptadenia help in absorption of nutrients

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT, 5 LT | Liquid.

- For customized specifications and packing – contact us.

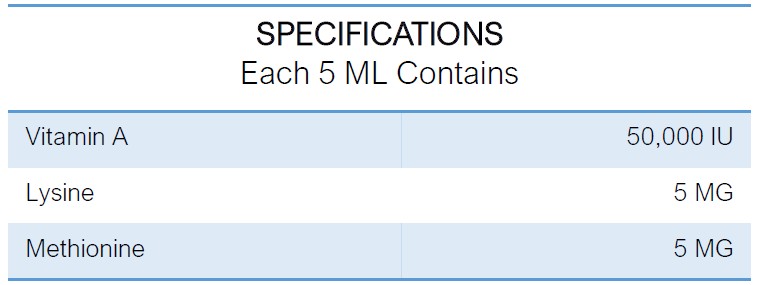

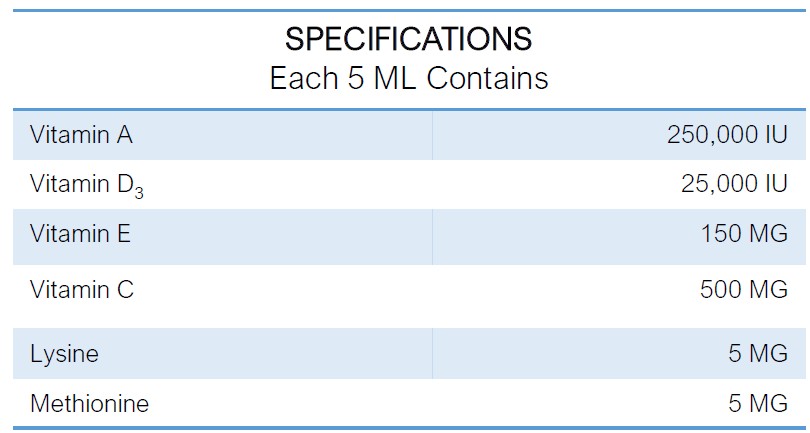

INTERMIX – INTERMIX ASOL

Water Miscible Vitamin A Concentrate

- ADVANTAGES:

- Ensure proper development & repair of epithelial cells

- Important for building immunity by reactivating macrophages

- Checks retarded and stunted growth

- Ensures production and hatchability

- Prevents poor plumage and sticky discharge from the eyes and nostrils

- Lasts longer – sealed under Nitrogen

- PACKING: 250 ML, 500 ML, 1 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

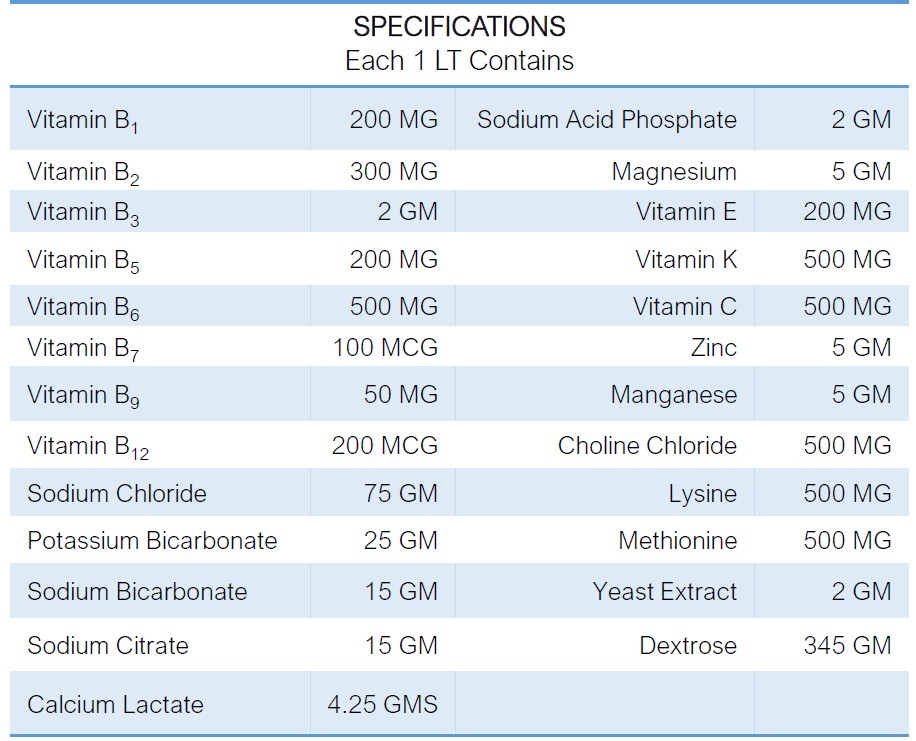

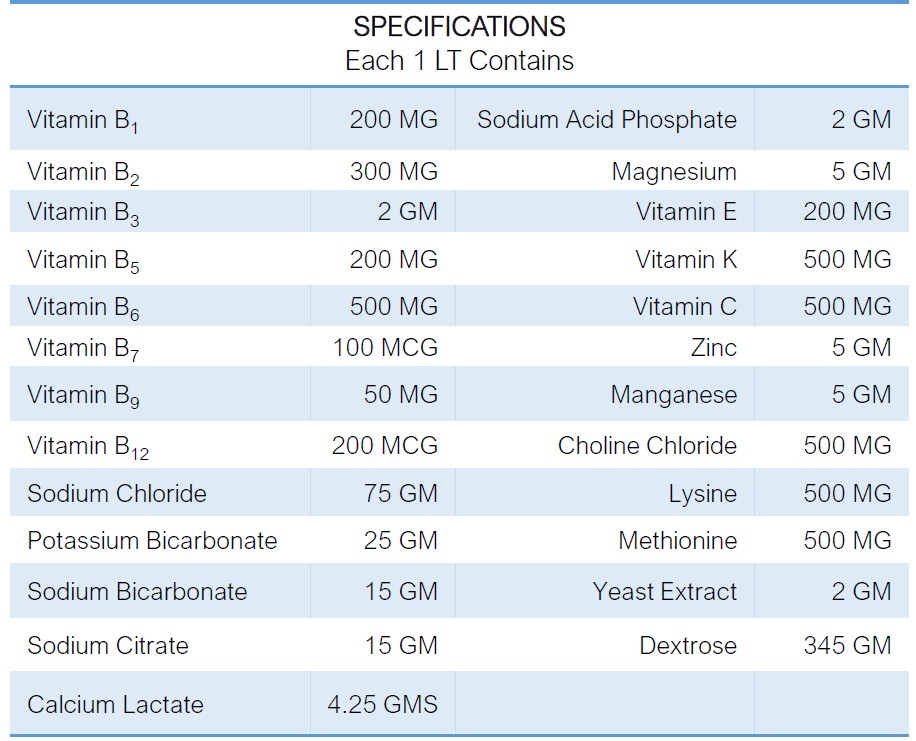

INTERMIX – B-ELECTROPLUS

Blend of B Complex, Electro Salts & Energy Boosters

- ADVANTAGES:

- Assists production of homogeneous flocks & reduces early chick mortality

- Adequate supplement during period of stress and digestive upset

- Yeast provides enzymes for phosphorus, fat, protein digestion & inactivate toxins

- Rich source of carbohydrate with other energy boosters

- Choline Chloride protects liver from toxins and fatty changes

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 10 LT Can | Liquid.

- For customized specifications and packing – contact us.

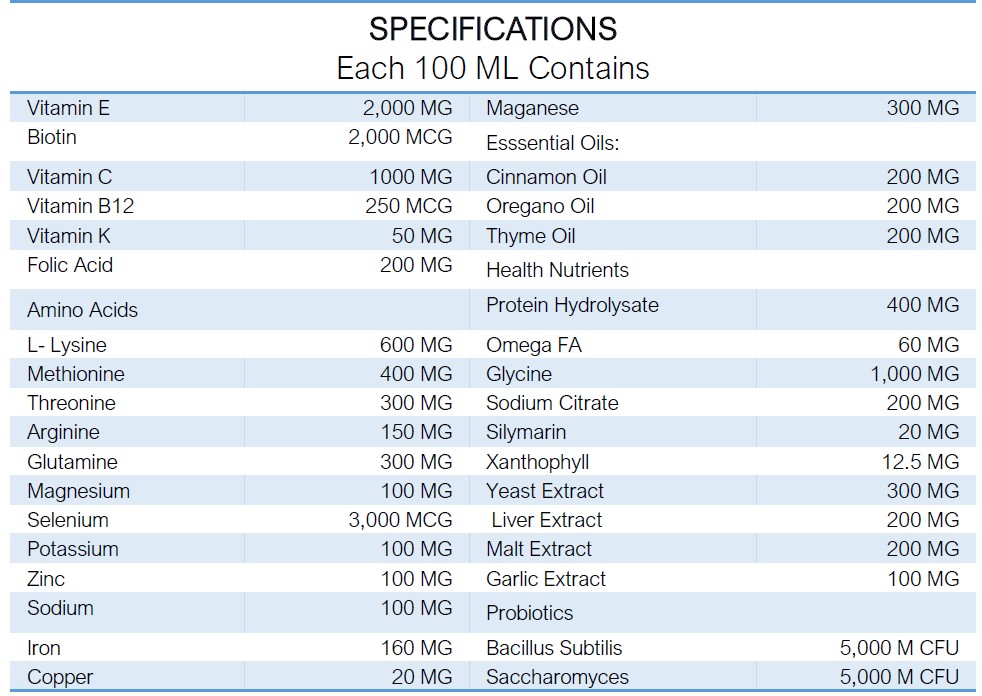

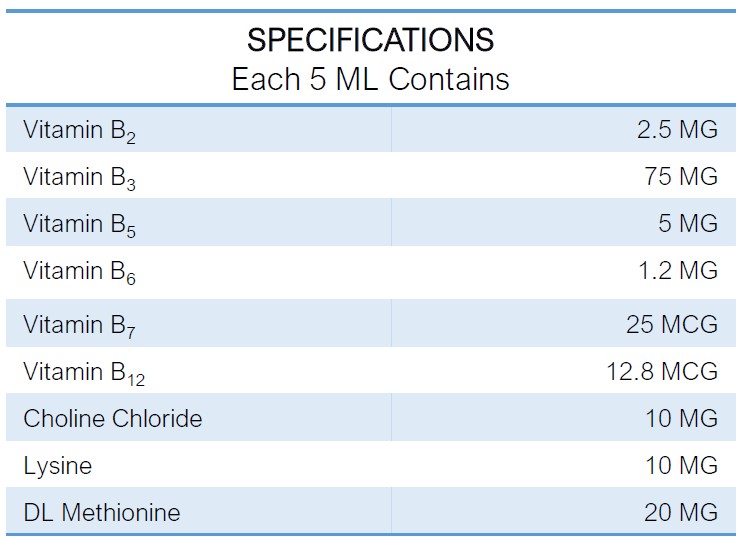

INTERMIX – BESOL

B Complex Concentrate with Amino Acids Essential Oils & Nutrients

- ADVANTAGES:

- B-complex requirement when feed uptake is reduced due to stress

- Restores normal metabolic functions and feed consumption in off-feed conditions

- Ensures normal growth, egg production, hatchability & gait by correcting riboflavin deficiency

- Checks convulsive movements, head retraction & abnormal excitability caused by pyridoxine deficiency

- Improves haemopoiesis growth and functioning of nerve cells by adequate B12 intake

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Feed Mixing: 3-5 GM/KG of feed

- Pond water: 100 GM in 5 Liter water to make fresh solution for mixing in 1 acre of pond area. Or as advised by nutritionist/veterinarian.

- PACKING: 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

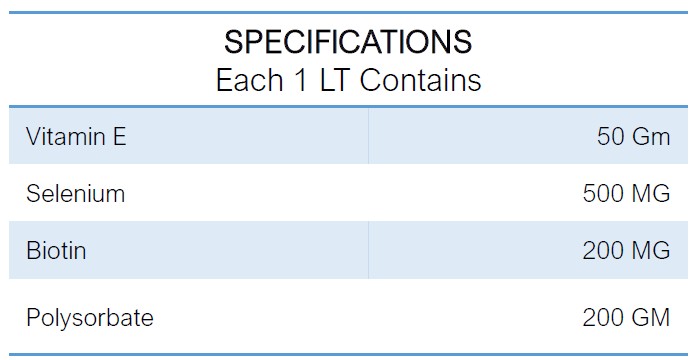

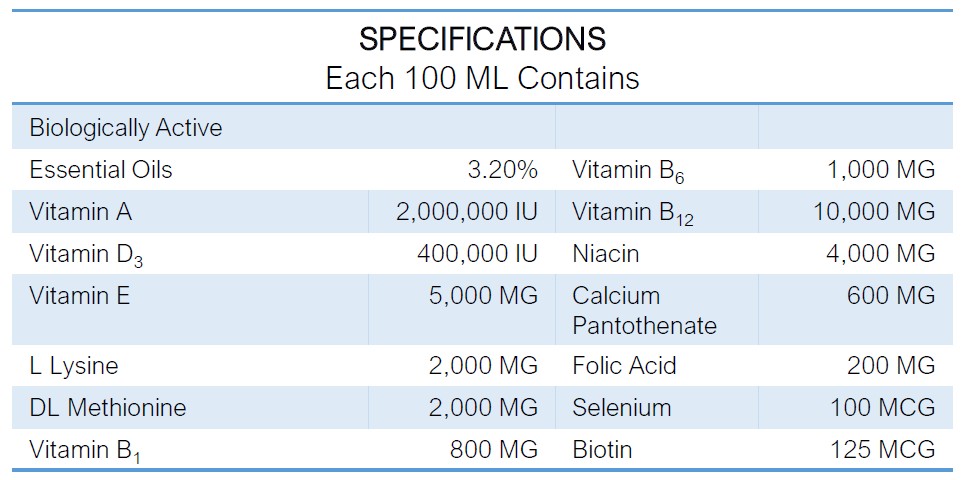

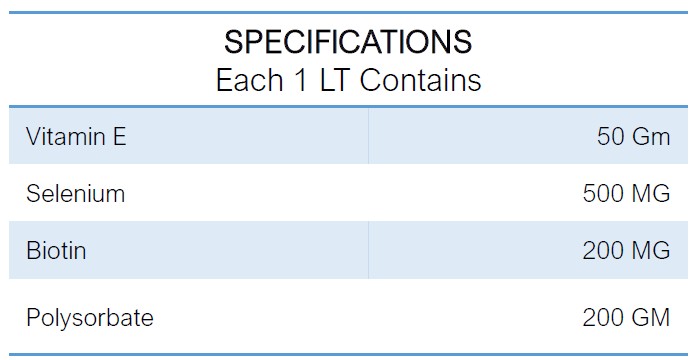

INTERMIX – BIOSELVIE

Immunity Booster with Selenium, Vitamins E, Biotin & Antioxidant

- ADVANTAGES:

- Contains strong antioxidants Vitamin E and Selenium

- Improves hatchability and muscular strength

- Improves defense mechanism

- Improves response during post vaccination and viral diseases

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

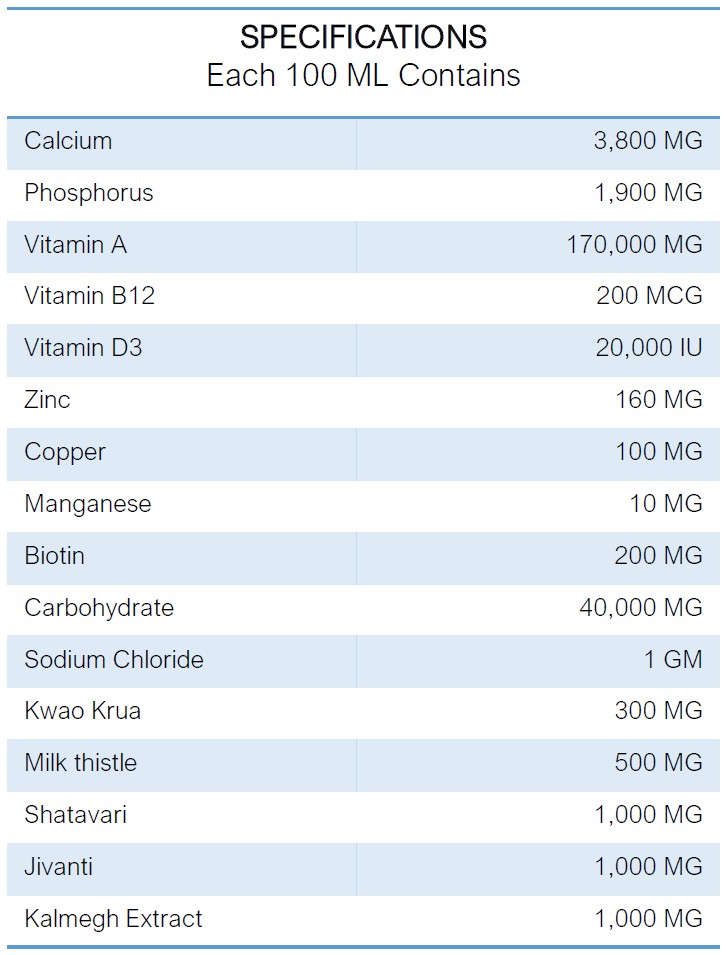

INTERMIX – CALCIVITE-H

Herbal Supplement with Calcium, Phosphorus Vitamins A,

D3, E & B12

- ADVANTAGES:

- Source of needed nutrients for alleviation of stress

- Vitamin D3 for better absorption and assimilation of Calcium and Phosphorous

- Vitamin B12 for haemopoiesis and toned up neuronal function

- Pre & post calving administration eliminates chances of milk fever

- Asparagus & Leptadenia improve absorption of nutrients and enhance lactogenesis and galactopoiesis

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT, 20 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – CALCIVITE-H-DS

Calcium Tonic with Synergistic Nutrients

- ADVANTAGES:

- Prevents breakage of eggs

- Prevents leg weakness, ensures faster growth and stronger bones

- Vitamin D3 is necessary for absorption & assimilation of Calcium & Phosphorous

- Vitamin A, E & Selenium improve neurological functions

- Asparagus and Leptadenia help in absorption of nutrients

- Lasts longer – sealed under Nitrogen

- PACKING: 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

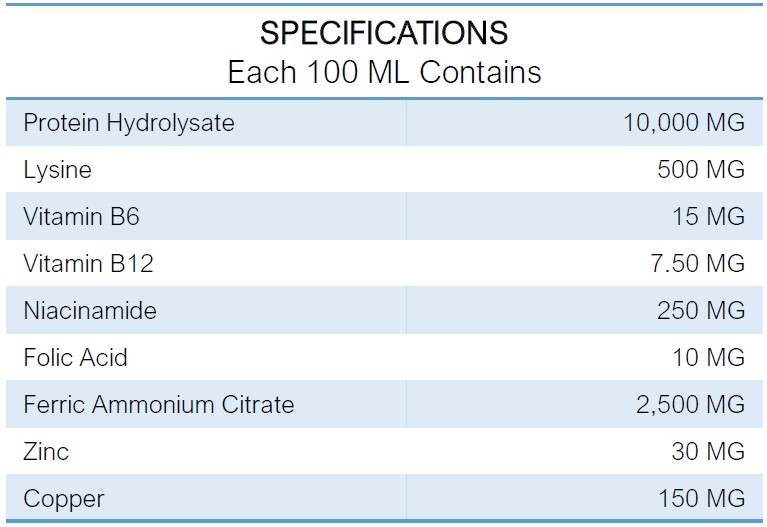

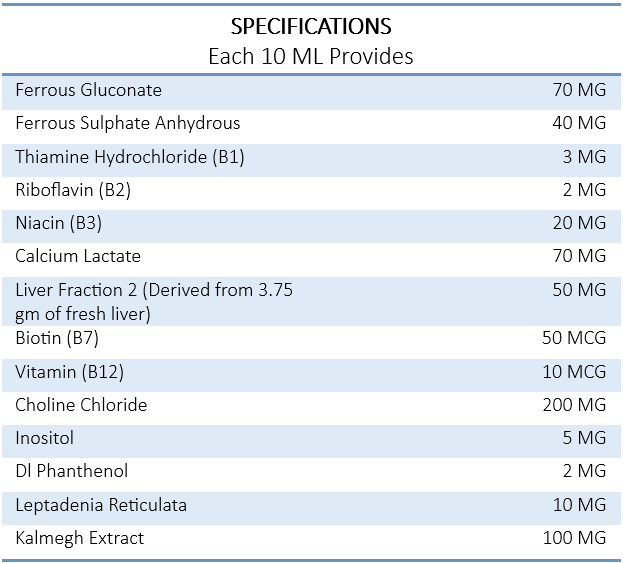

INTERMIX – HIPROVIT-1

Blend of Protein, Iron & Vitamin Concentrate for Growth

- ADVANTAGES:

- Perfect remedy during and post stress episodes

- Improves feed conversion and weight gain in broilers

- Corrects anaemic and morbidity conditions and thereby improves production

- Assures optimum liver function and metabolism

- Ideal during pregnancy, lactation, weakness and debility in canines and other mono gastric animals

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – IMOTECH (STRONG)

Immunity Enhancer Antistressor & Antioxidant

- ADVANTAGES:

- Enhances natural and non-specific immunity

- Enhances phagocytosis and improves defense mechanism

- Protects from production loss and improves muscular strength

- Acts an antioxidant and reduce cell membrane damage

- Improves hatchability in breeders and body weight in broilers

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

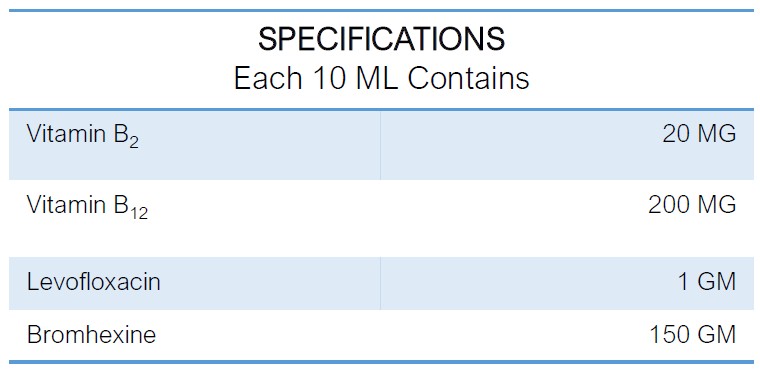

INTERMIX – LEVOPLUS-BH

Enhanced Egg Production & Flock Weight

- ADVANTAGES:

- Safe

- Improved Feed Conversion Ratio (FCR)

- B12 helps improve symbiosis

- Well accepted through water

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

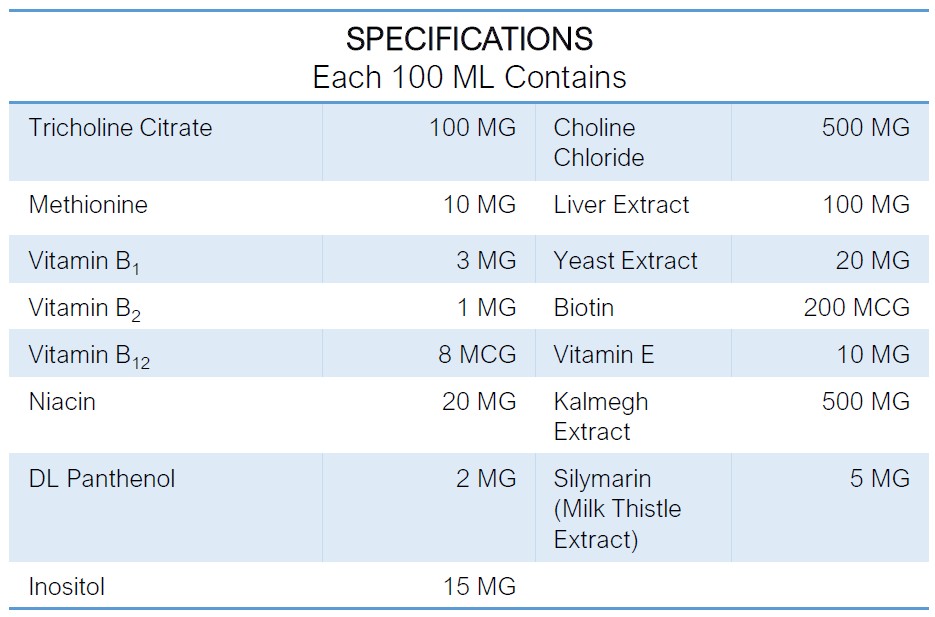

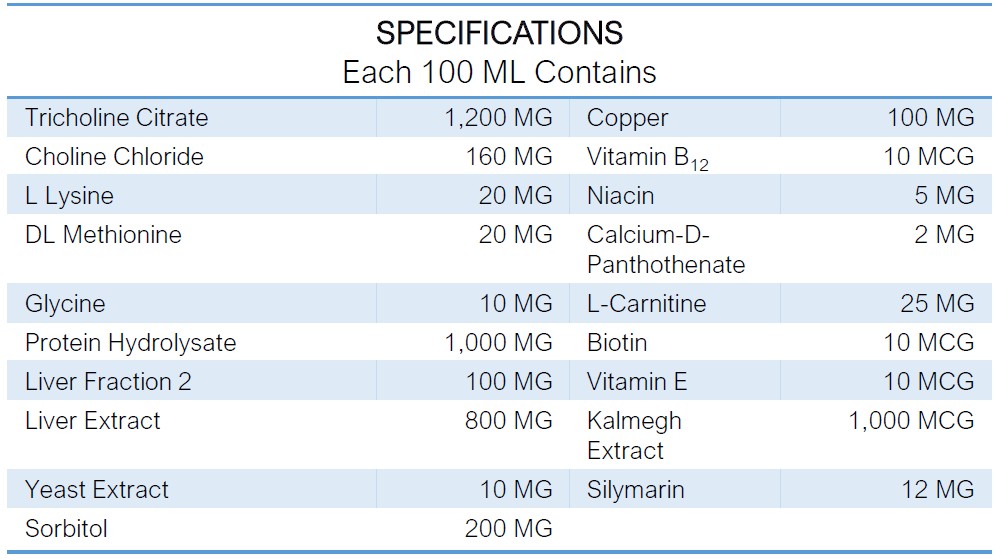

INTERMIX – LIVDIGEST

Liver Tonic

- ADVANTAGES:

- Perfect combination of metabolic stimulants, antioxidant, vitamins, detoxifiers and highly effective hepatic stimulant herbs

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function, improves immunity

- Silymarin helps in regenerating hepatocytes

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Feed mixing: 10-15 ML/KG of feed

- Pond water: 2 Litre/Acre of pond water

- Or as advised by nutritionist/veterinarian

- PACKING: 1 LT Bottle, 5 LT Jar | Liquid.

- For customized specifications and packing – contact us.

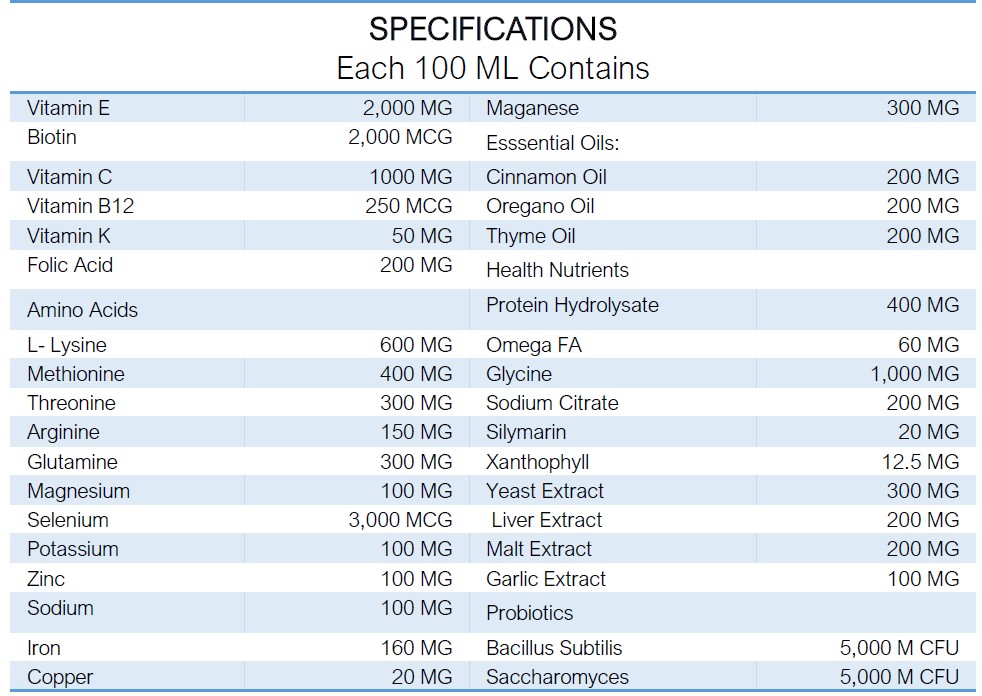

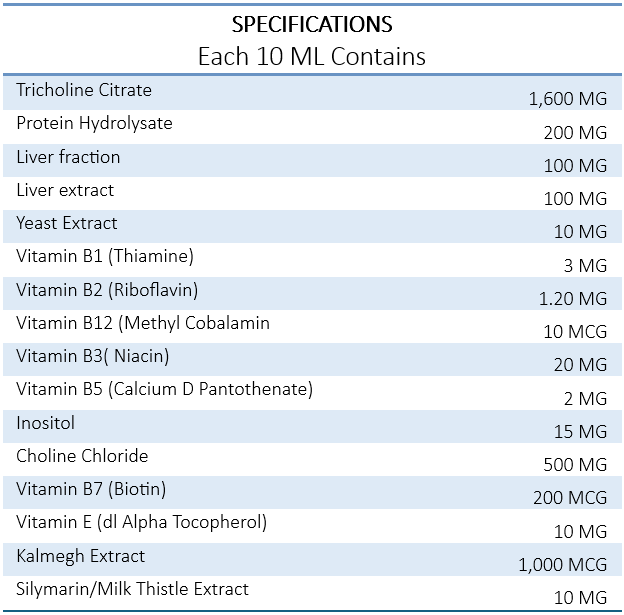

INTERMIX – LIVDIGEST STRONG

Superior Liver Tonic for Protection & Performance

- ADVANTAGES:

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function & metabolic processes, improves immunity

- Combats stress, improves feed conversion & growth

- Useful in hepatic damage due to fungal and other hepatotoxins

- Mobilizes fat from liver and protects liver from fatty changes & cirrhosis

- Silymarin helps in regenerating hepatocytes (liver cells)

- PACKING: 1 LT, 5 LT, 20 LT| Liquid.

- For customized specifications and packing – contact us.

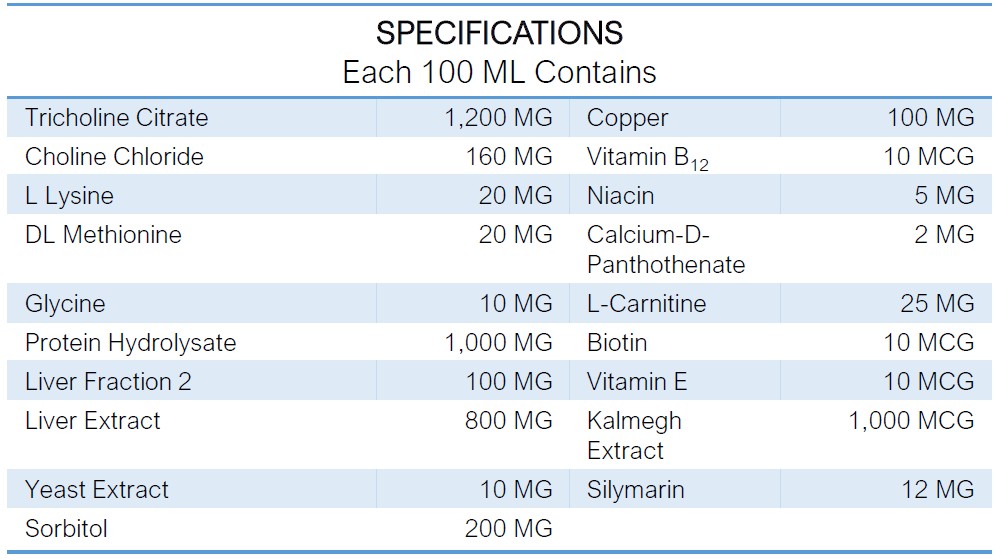

INTERMIX – LIV-TOP

Liver Tonic for Protection & Performance

- ADVANTAGES:

- Prevents liver disorders and improves liver function

- Mobilizes fat from the liver, prevents fatty liver syndrome

- Source of Vitamin B12 & Folic acid

- Improves defense mechanism, detoxifies liver

- Ensures faster recovery after antibiotic therapy

- Silymarin helps in regenerating hepatocytes (Liver cells)

- Lasts longer – sealed under Nitrogen

- PACKING: 5 LT, 20 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – MYTIBIND EXPO

Broad Spectrum Toxin Binder

- ADVANTAGES:

- Inhibits toxin producing agents and aflatoxins

- Ability to bind multiple mycotoxins and to improve FCR

- Inhibits Salmonella, E. Coli, Clostridium and other bacterial infections

- Improves egg production in Layers and body weight in Broilers

- Improves water quality by reducing pH & improves feed safety

- Reduces hazardous mycotoxins within the gastro-intestinal tract

- Essential oils improve metabolism and enhance immunity

- Choline chloride protects liver from toxins and fatty change

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

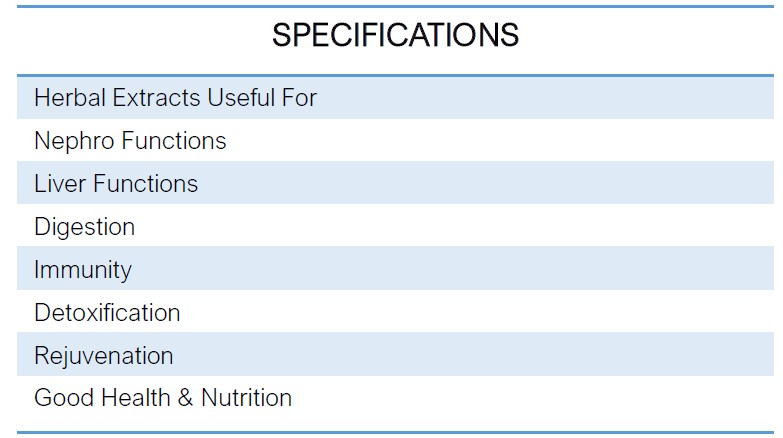

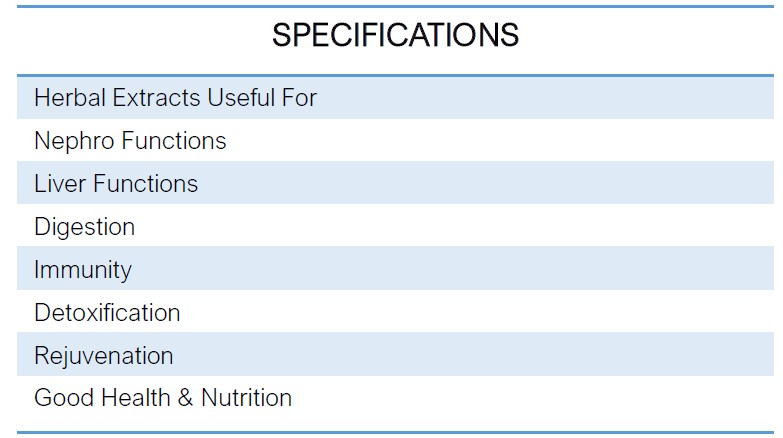

INTERMIX – NEPHROCORP

Herbal Tonic for Renal Function & Detoxification

- ADVANTAGES:

- Protection against gout, ascites and urinary tract infection

- Useful against infectious microorganism

- Effective diuretic and alkalizer

- Hepatic stimulant with anti-hepatotoxic

- Useful in urinary system disorders

- Improves digestion and provides rejuvenation

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – RENOTONE

Strong Nephro Health Tonic

- ADVANTAGES:

- Helps in normal functions of kidneys

- Acts as an effective diuretic, alkalizer, and nephroprotective agent

- Works as a hepatic stimulant; useful in urinary system disorders

- Helps in the prevention of gout

- Acts as an immuno-stimulant

- Improves arthritic conditions

- Improves digestion and provides rejuvenation

- PACKING: 1 LT, 5 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

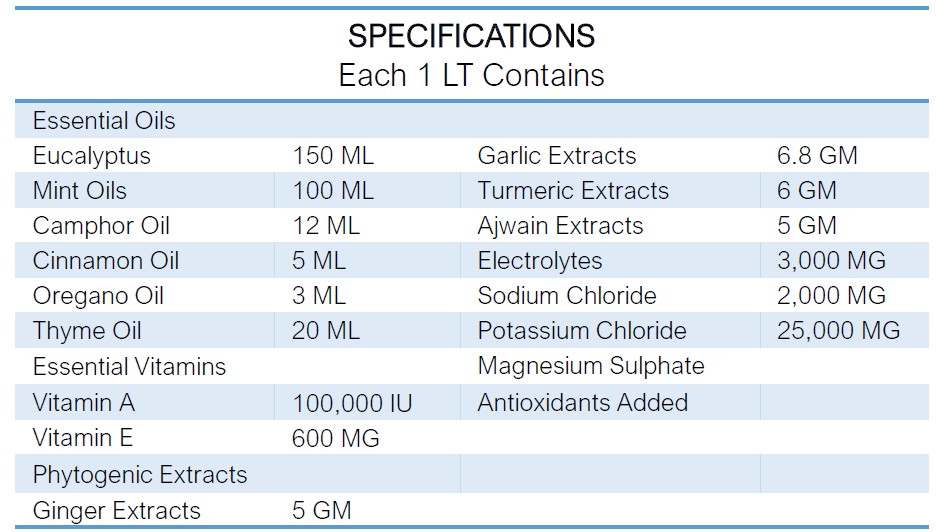

INTERMIX – RESPOFAST

Respiratory Relaxant & Decongestant

- ADVANTAGES:

- Essential Oils strengthen functioning of respiratory system

- Relief from broncho-congestions, reduces mucus secretion

- Reduces vaccination stress. Benefit before and post vaccination

- Useful in sneezing, coughing and labored breathing

- Phytochemicals in herbs have strong anti-bacterial activity

- Electrolytes protect birds from loss of water during respiratory diseases

- Lasts longer – sealed under Nitrogen

- PACKING: 250 ML, 500 ML, 1 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – ROTO

Blend of Essential Oils & Nutrients

- ADVANTAGES:

- Significant effect on gut health in poultry, limiting the need for antibiotics

- Prevents fungal, viral and bacterial ailments

- Helps in digestive issues like sour crop, vent gleet, pasty butt and diarrhea

- Improves the condition of the skin and plumage

- Restores health, growth and egg production by correcting metabolic process

- Improves carbohydrates, lipid and protein metabolism

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

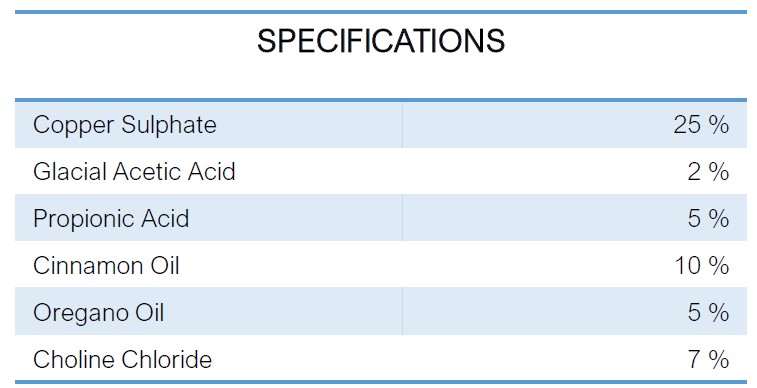

INTERMIX – TOXICORP EC

Mycotoxin Binder & Mold Inhibitor

- ADVANTAGES:

- Inhibits toxin producing agents and aflatoxins

- Improves egg production in layers and body weight in broilers

- Improve water quality by reducing pH & improves feed safety

- Reduces hazardous mycotoxins within the gastro

- Essential oils improve metabolism and enhance immunity

- Choline Chloride protects liver from toxins and fatty changes

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – WDS

Concentrate of Vitamins A, C, D & E

- ADVANTAGES:

- Prevents stress arising due to handling infection, medication and environmental changes

- Restores normal health, growth & production

- Improves body resistance immunity

- Check retarded growth, low hatchability & egg production

- Provides essential Amino Acids -Lysine & Methionine

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

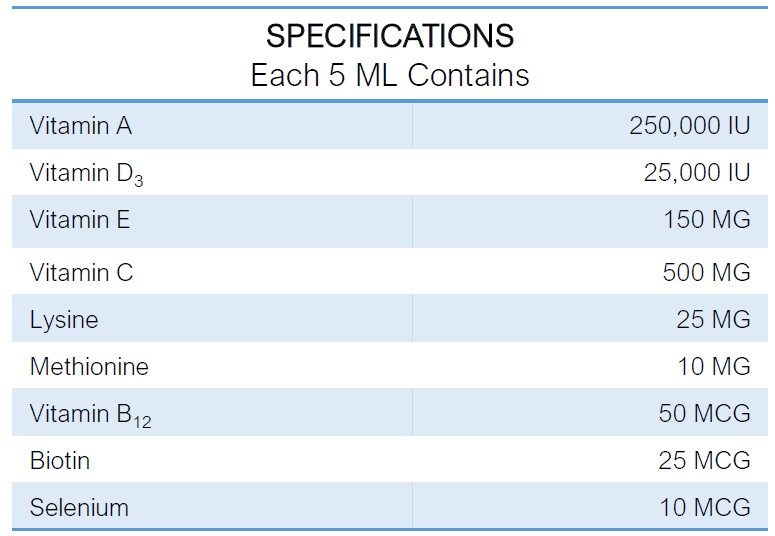

INTERMIX – WDS (EXPO)

Concentrate of Vitamins A, C, D & E with Antioxidants

- ADVANTAGES:

- Prevents stress arising due to handling infection, medication and environmental changes

- Improves body resistance and capacity to fight viral, bacterial and protozoan infections

- Selenium improves carbohydrate, lipid and protein metabolism

- Enriched with essential amino acids-Lysine & methionine in adequate quantities

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

The Need

Nutrient Deficiencies in Natural Feed Ingredients: grazing items often lack adequate minerals and vitamins, leading to poor milk yields and reproductive health issues. Journal of Food and Beverages, Feed Navigator

Improving Feed Efficiency & Productivity: additives increase milk production, improve reproductive performance, and overall health. Feed Navigator

Combating Mycotoxins & Other Feed Contaminants: mycotoxins in feed reduce performance and lead to health issues. Toxin binders and liver tonics in feed help mitigate these risks. Feed Strategy

Reducing Antibiotic Use & Promoting Sustainable Farming: probiotics and herbal additives reduce reliance on antibiotics, improving gut health, critical for sustainable farming. Lark Engineering

Supporting Economic Growth: livestock is a significant contributor to rural economy. Better productivity helps farmers meet demand for meat and milk, thus improving livelihoods.

Advantages

- Longer lasting premix, due to reduced reactivity of nutrients from environment exposure – from cutting-edge Microencapsulation Technology.

- Controlled release of nutrients in feed – from cutting-edge Microencapsulation Technology.

- Happy consumers due to assured nutrient delivery – from cutting-edge Microencapsulation Technology.

- Cost effective nutrient fortification – no investment in new equipment.

- Assured & consistent quality – COA available on request.

- Made from safe materials – SDS available on request.

- Brand loyalty & trusting consumers.

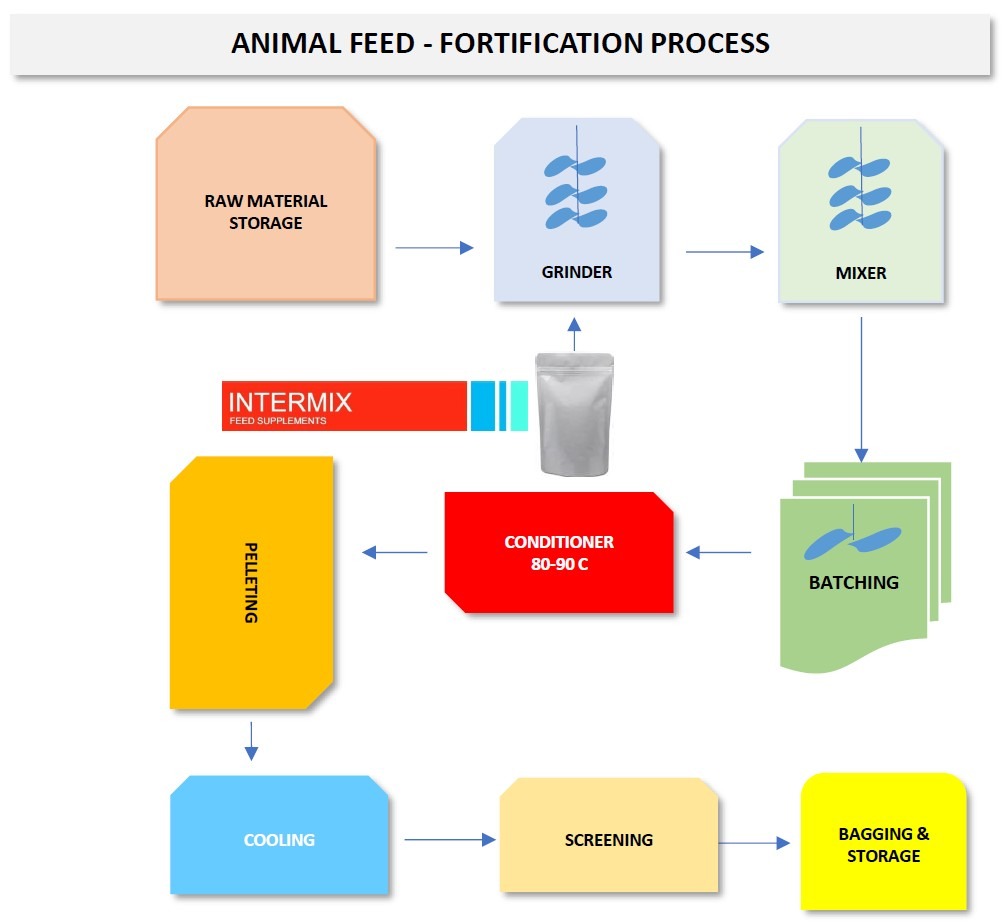

Process

- Powders:

- Raw Material Storage: Raw materials viz. grains, protein sources, feed premixes & other ingredients are stored in silos/warehouse.

- Grinding: Materials are ground into uniform particle sizes for mixing.

- Mixing: Ground ingredients are mixed, then feed premixes added.

- Batching: Mixed feed is divided into batches as per formula for adding required ingredients for processing.

- Conditioning: Feed is steamed in conditioner to soften for pelleting.

- Pelleting: Conditioned feed mix is fed into pellet mill to form pellets.

- Cooling & Screening: Hot pellets are cooled in a cooling chamber to solidify pellets, reduce moisture, then screened to remove fines.

- Storage & Bagging: Finished pellets are stored in bulk then bagged for distribution.

- Watch Feed Fortification Process

- Liquids:

- Through drinking water, mixing with feed or as advised by veterinarians.

INTERMIX – BESOL WS

B Complex Concentrate with Amino Acids Essential Oils & Nutrients

- ADVANTAGES:

- Designed to meet B-Complex requirement through drinking water especially when feed uptake is reduced due to “stress”

- Restores normal metabolic functions and feed consumption in off-feed conditions

- Ensures normal growth, egg production, hatchability and gait by correcting Riboflavin deficiency

- Checks convulsive movements, head retraction & abnormal excitability caused by Pyridoxine deficiency

- Improves haemopoiesis growth and functioning of nerve cells by adequate B12 intake

- PACKING: 100 GM, 500 GM | Powder.

- For customized specifications and packing – contact us.

INTERMIX – BIOSELVIE WD

Strong Antioxidant & Immunity Booster

- ADVANTAGES:

- Improves defense mechanism

- Improves hatchability, growth, egg production and muscular strength

- Improves immune response during post vaccination and viral diseases

- Vitamin E and Selenium act as antioxidant and prevent tissue damage

- Biotin improves carbohydrate, lipid and protein metabolism

- Lasts longer – sealed under Nitrogen

- PACKING: 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

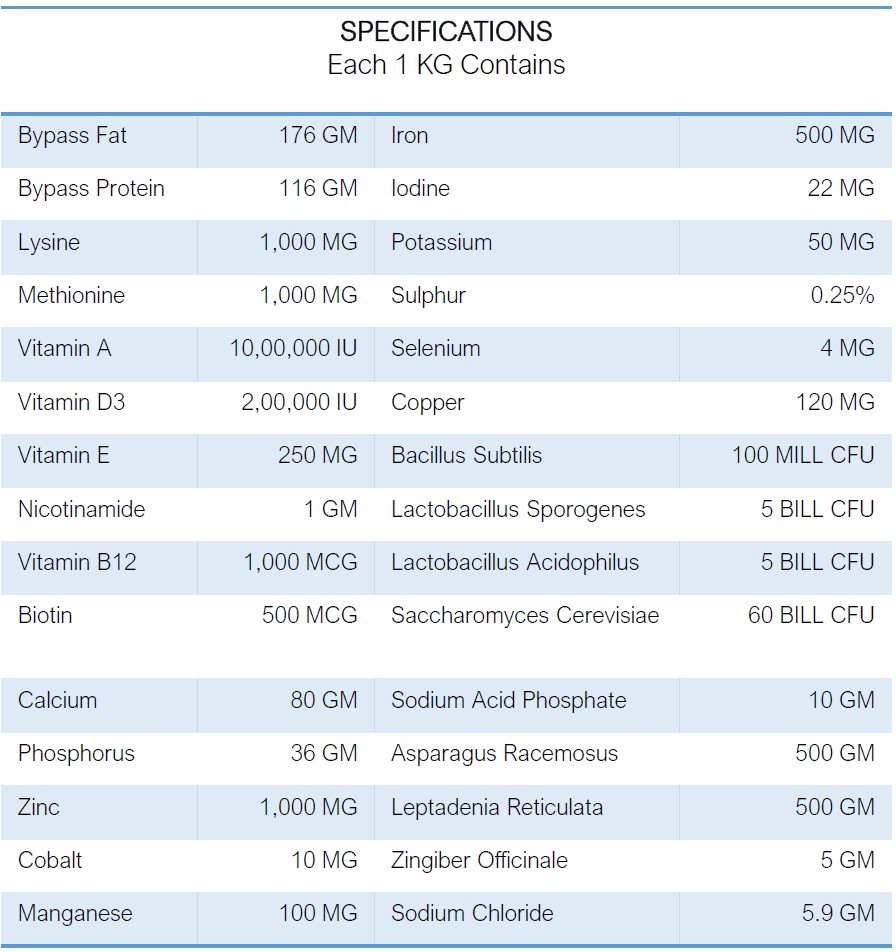

INTERMIX – BYPASS NUTRI (VET)

Bypass Fat & Bypass Protein

- ADVANTAGES:

- Improves milk yield and fat percentage significantly

- Improves rumen micro flora function

- Makes defense mechanism strong in a natural way

- Improves fertility and conception rate

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Pouch, 5KG Pouch, 25 KG (5×5 KG), 25 KG (No subpack) Bag | Powder.

- For customized specifications and packing – contact us.

INTERMIX – D3

Vitamin D3 Premix

- ADVANTAGES:

- Ensures better mobilization and absorption of calcium & phosphorus from intestine

- Checks wing and leg lameness in poultry birds

- Improves egg production, shell quality & hatchability

- Enhances feed conversion & growth rate in broilers

- Livestock: Useful in metabolic disorders responsible for Calcium

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – D3 STRONG

Superior Vitamin D3 Premix for Poultry and Livestock Supplementation

- ADVANTAGES:

- D3 strong ensures better mobilization and absorption of Calcium & Phosphorus from the intestines

- Checks wing and leg lameness in poultry birds

- Improves egg production, shell quality & hatchability

- Enhances feed conversion & growth rate in broilers

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – ELECTROCORP WS (VET)

Perfect Combination for Electrolytic Balance

- ADVANTAGES:

- Immediately corrects electrolyte imbalance resulting from stressful conditions

- Restores mineral & fluid loss instantly in all species

- Promptly controls dehydration caused by diarrhea or High temperature transportation or vigorous exercise

- Convenient to administer through feed or drinking water

- PACKING: 500 GM, 1 KG, 5 KG, 25 KG (5 x 5 KG SUB PACKS) | Powder.

- For customized specifications and packing – contact us.

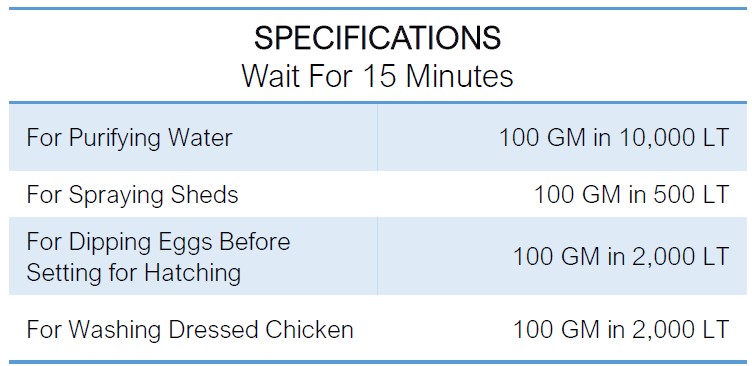

INTERMIX – ECOKILL

Water Sanitizer

- ADVANTAGES:

- Prevents bacteria, virus, and fungi

- Prevents re-contamination upto 72 hours

- Does not alter taste or pH of water

- Helps in faster sedimentation of physical impurities

- Lasts longer – sealed under Nitrogen

- PACKING: 100 GM, 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – IMOTECH STRONG

Superior Immunity Enhancer, Antistressor and Antioxidant Supplement

- ADVANTAGES:

- Enhances Natural and non-specific immunity

- Enhances phagocytosis and improves defense mechanism

- Improves vaccine titer and relieves stress

- Improves metabolism of carbohydrates, lipids and proteins

- Protects from production loss and improves muscular strength

- Acts as antioxidant and reduces cell membrane damage

- Improves hatchability in Breeders and Body weight in Broilers

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG, 25 KG Pouch | Powder.

- For customized specifications and packing – contact us.

INTERMIX – LIVDIGEST

Water Miscible Liver Tonic for Protection & Performance Supplementation

- ADVANTAGES:

- Perfect combination of metabolic stimulants, antioxidants, vitamins, detoxifiers, and highly effective hepatic stimulants.

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function

- Improves metabolic processes

- Combats stress and improves FCR

- Useful in hepatic damage due to fungal and other hepatotoxins

- Mobilizes fat from liver and protects liver from fatty changes & cirrhosis

- Improves immunity, Egg production and body weight

- Supports nephrotic tissue functions

- PACKING: 1 KG Pouch, 25 KG (5x5KG) | Powder.

- For customized specifications and packing – contact us.

INTERMIX – MILKOCORP AD3 VET

Milk Booster with Calcium

- ADVANTAGES:

- Improves milk production and fat percentage

- Improves growth rate and health

- Improves liver function

- Improves metabolism of carbohydrate, protein and fat

- Improves immunity and performance

- PACKING: 500 GM, 1 KG Pouch, 5 KG | Powder.

- For customized specifications and packing – contact us.

INTERMIX – Veterinary Mineral Mixture Type 1

Mineral Mixture as per IS-1664:2002 T1

- ADVANTAGES:

- Enhances Health, Growth, Mass and Weight

- Prevents Fatigue, Anorexia, G.I. Disturbances & Neurological Symptoms

- Improve Metabolism and Capacity of Feed Intake

- Increases Milk Production and Improves Fertility

- Provides Antioxidant

- As per IS–1664:2002 Type 1 standards

- Lasts longer – sealed under Nitrogen

- PACKING: 5KG Pouch, 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

INTERMIX – Mineral Mixture Type 2

Veterinary Mineral Mixture –Type 2

- ADVANTAGES:

- Enhances Health, Growth, Mass and Weight

- Calcium and Phosphorus help to Increase Milk Production

- Improves Energy Metabolism and Capacity of Feed Intake

- Important for Integrity of Born and Teeth

- Iodine for Synthesis of Thyroid Hormones

- Better Immune Response – Better Resistance Against Disease

- As per IS–1664-2002 Type 2 standards

- Lasts longer – sealed under Nitrogen

- PACKING: 5KG Pouch, 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

INTERMIX – MULTIMIX FORTE

Multi-Vitamin & Enzymes Mixture with Iron

- ADVANTAGES:

- Enhances health, growth, mass, weight, production, and prevents deficiency in animals

- Improves metabolism and capacity of feed intake

- Well accepted for poultry and livestock ration

- Can be used in manufacturing of feed supplements for various species

- Lasts longer – sealed under Nitrogen

- PACKING: 30 KG DRUM | Powder.

- For customized specifications and packing – contact us.

INTERMIX – MYTIBIND EXPO (IMPROVED)

Broad Spectrum Toxin Binder

- ADVANTAGES:

- Organic acids – act as mold inhibitor and prevent formation of mycotoxins

- Ability to blind T-2 Toxins and helps in absorption of nutrients

- Activated Charcoal – inactive chemical toxins not absorbed by HSCAS and MOS

- Base prevents growth of pathogens, mobilizes nutrients for better absorption

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Pouch, 5 KG, 25 KG (5x5KG), 25 KG (no sub-pack) Bag | Powder.

- For customized specifications and packing – contact us.

INTERMIX – ORTHOCAP

Calcium & Phosphorus Premix for High Skeletal Strength

- ADVANTAGES:

- Super strong doubles strength formula

- High bioavailability of natural Calcium and Phosphorous from MCHC

- Helps in faster growth with stronger bones

- Perfect source of organic minerals and collagen

- Vitamin D3 and C enhances absorption & assimilation of Calcium and Phosphorous

- Manganese improves metabolism of carbohydrate, fat and protein

- Citric acid (acidifier) maintains intestinal pH and improves absorption of Calcium and Phosphorous

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Feed mixing: 5-10 GM/KG of feed

- Pond water: 5-10 KG/Acre of pond water

- Or as advised by nutritionist/veterinarian

- PACKING: 1 KG Pouch, 5 KG Pouch, 25 KG Bag | Powder.

- For customized specifications and packing – contact us.

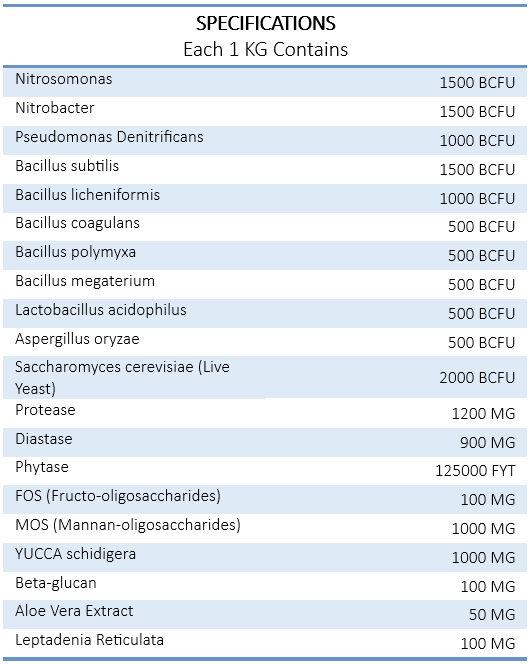

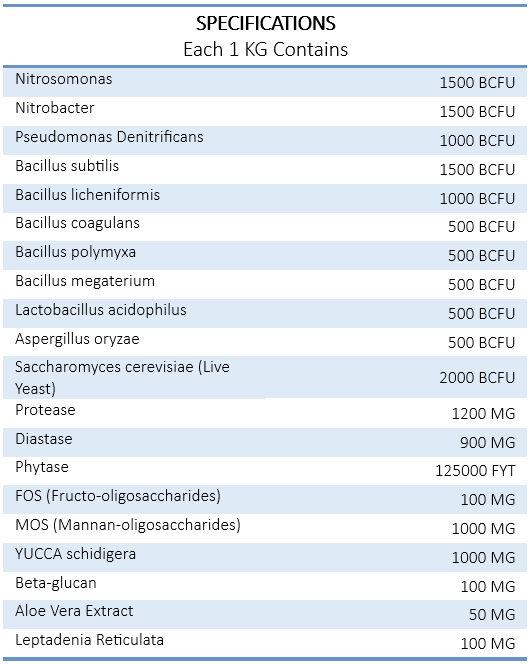

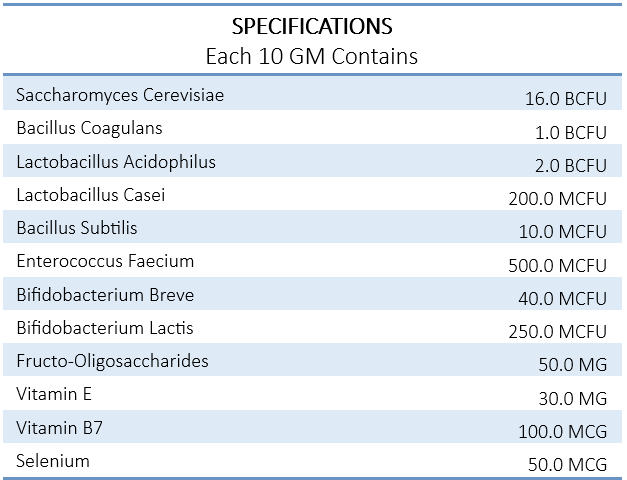

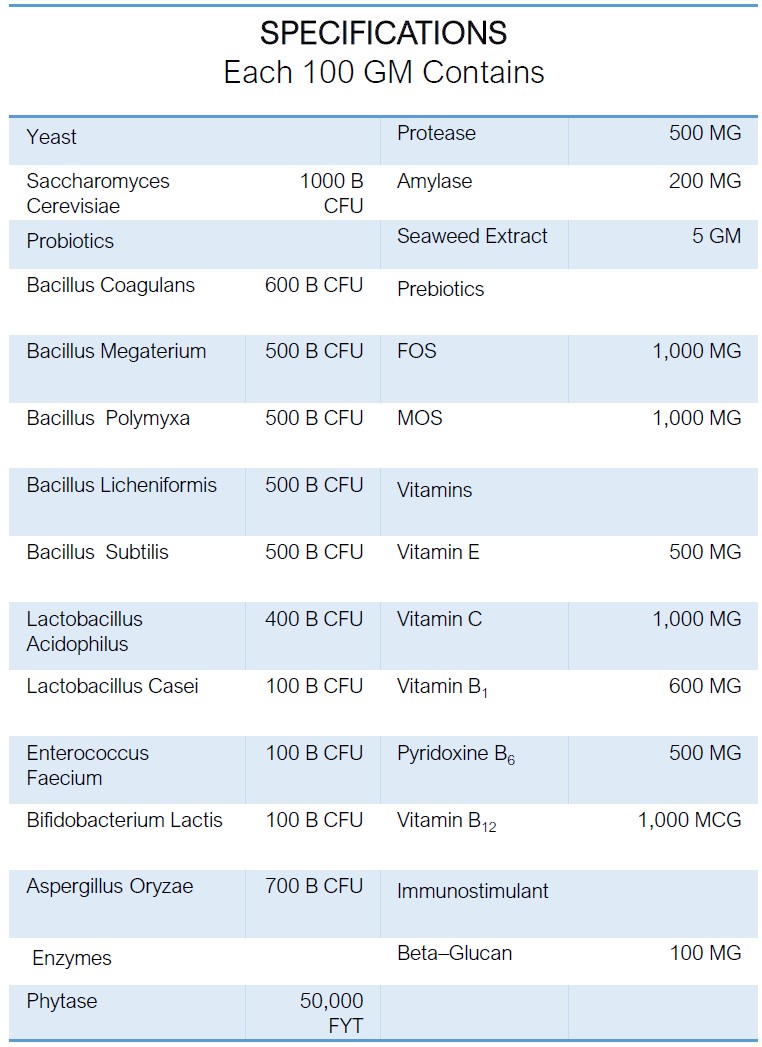

INTERMIX – PROBEE VET

Probiotics & Enzyme Premix

- ADVANTAGES:

- Livestock probiotic supplement containing over 20 billion CFU of natural bovine bacteria per serving of probiotic strains

- Serves a wide range of probiotics to reestablish healthy intestinal microflora

- Relieves stress from diet change, traveling, treatment, or vaccination

- Supports growth, stabilization of ruminant flora, increases weight and milk production

- Live yeast stabilizes ruminal pH, enhances fiber and carbohydrate digestion

- Improves the benefits of enzyme driven food production, and reduces bloating

- Competes with pathogenic microorganisms for the site of adherence on the intestinal surface

- Eliminates E. coli, Salmonella, and Aeromonas spp., as well as promotes immunity

- Vitamin E, Biotin, and Selenium improve immune response with antioxidant action

- Fructo-oligosaccharides (FOS) stabilize intestinal microflora and act as a prebiotic and residue-free

- ADMINISTRATION:

- Feed mixing: 5-10 GM/KG of feed

- Pond water: 5-10 KG/Acre of pond water

- Or as advised by nutritionist/veterinarian

- PACKING: 100 GM, 500 GM, 1 KG | Powder.

- For customized specifications and packing – contact us.

INTERMIX – SELVIE WD

Antioxidant & Immunity Booster

- ADVANTAGES:

- Vitamin E & Selenium act as antioxidants

- Improves immune systems

- Improves hatchability and muscular strength

- Improves immune response post vaccination and during viral diseases

- Prevents exudative diathesis and encephalomalacia

- Lasts longer – sealed under Nitrogen

- PACKING: 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – SUPERMIX NZ

Vitamin Premix for Layers

- ADVANTAGES:

- For Vitamin B group deficiency

- Enhances health, growth, mass weight and egg production in poultry

- Provides Vitamin D necessary for absorption of phosphates

- Carotenoids: improve egg production and egg yolk colour

- Lasts longer – sealed under Nitrogen

- PACKING: 5 KG Pouch, 25 KG (5×5 KG) Bag, 25 KG (5X5 KG) Drum | Powder.

- For customized specifications and packing – contact us.

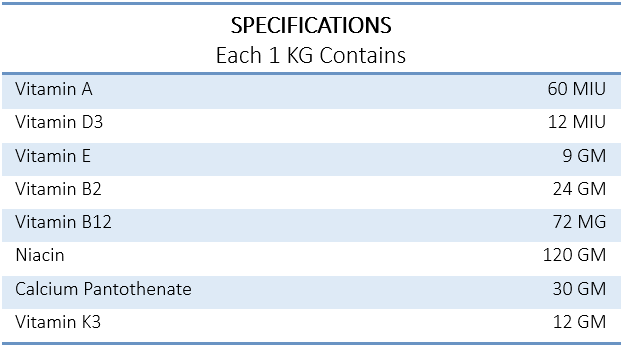

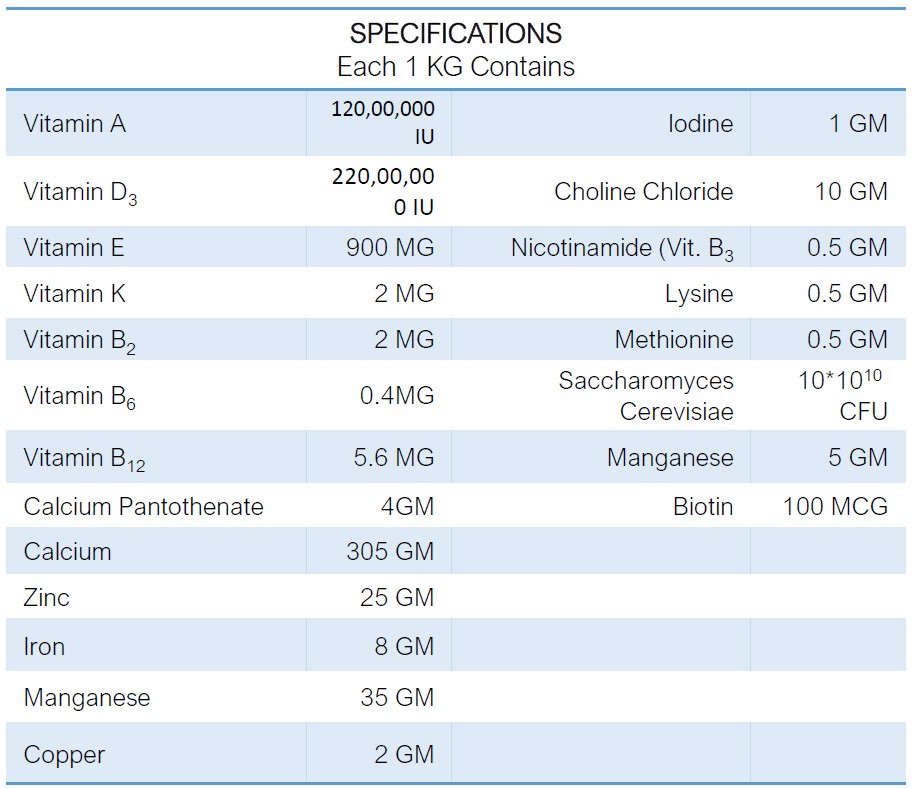

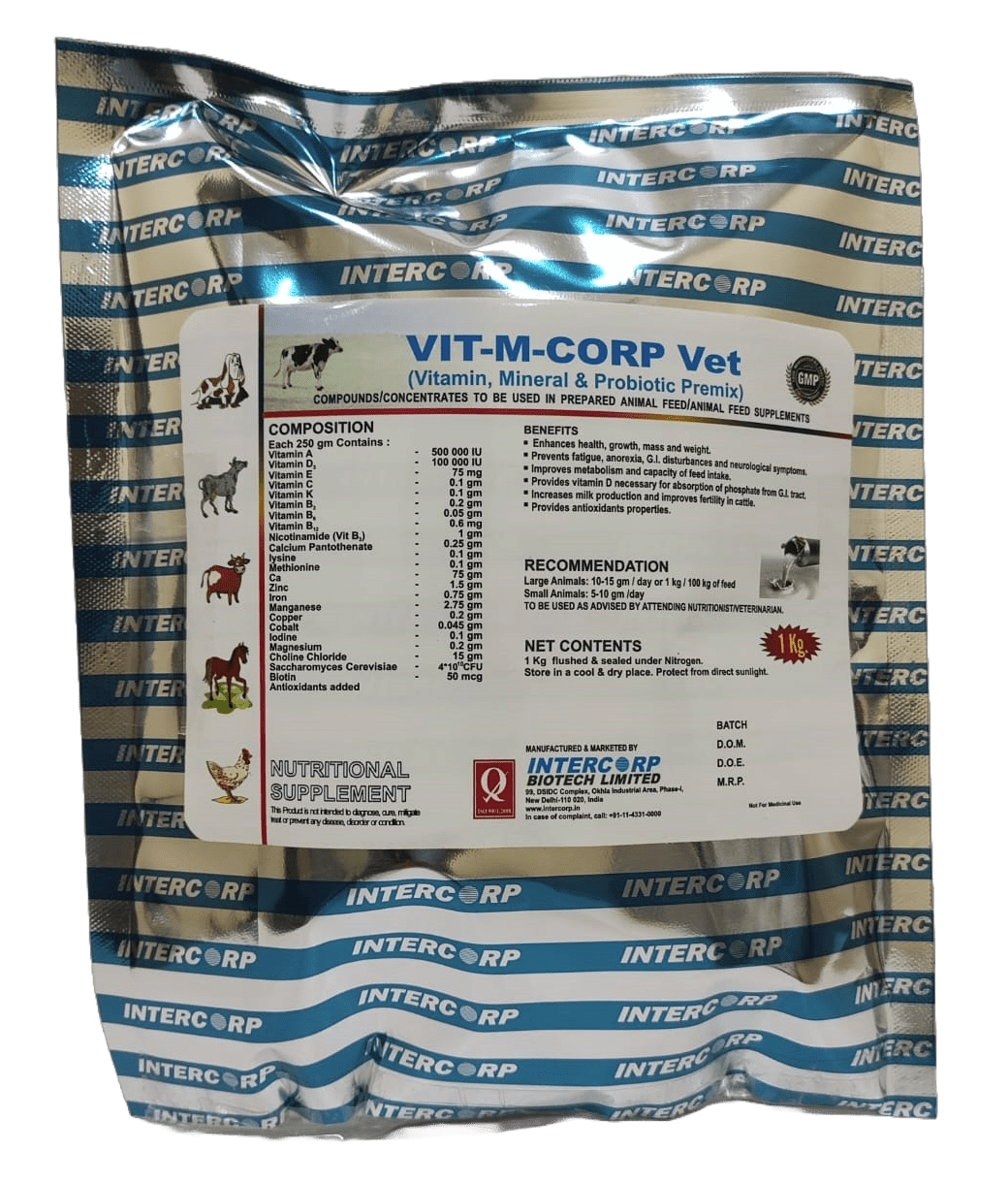

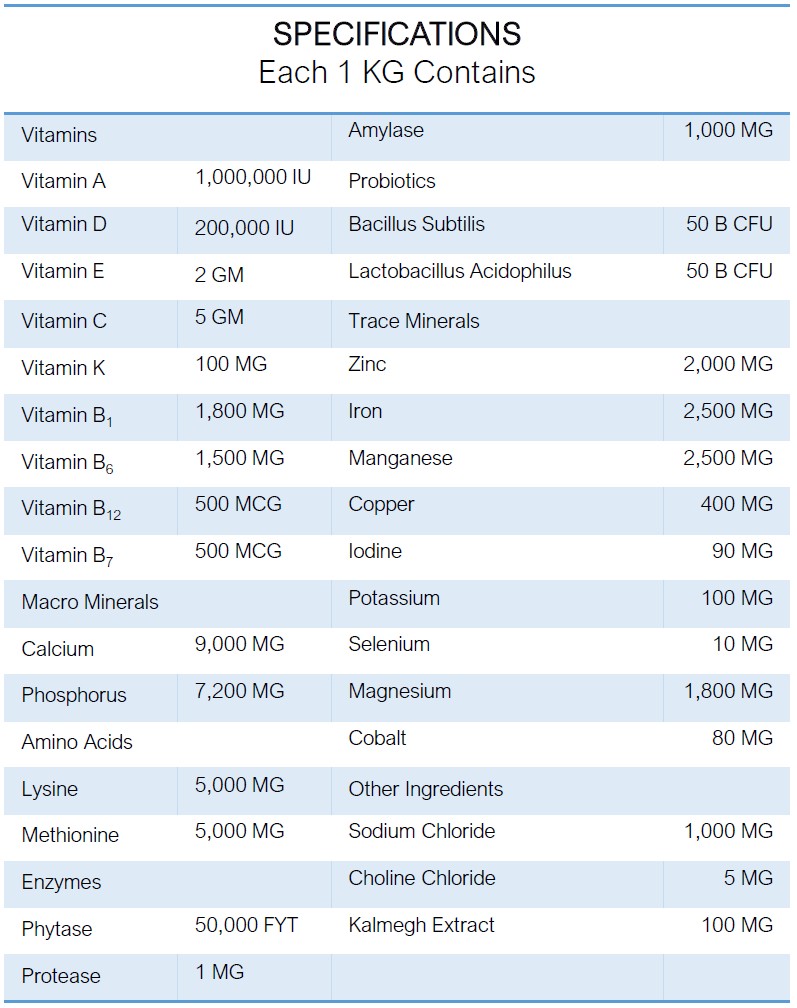

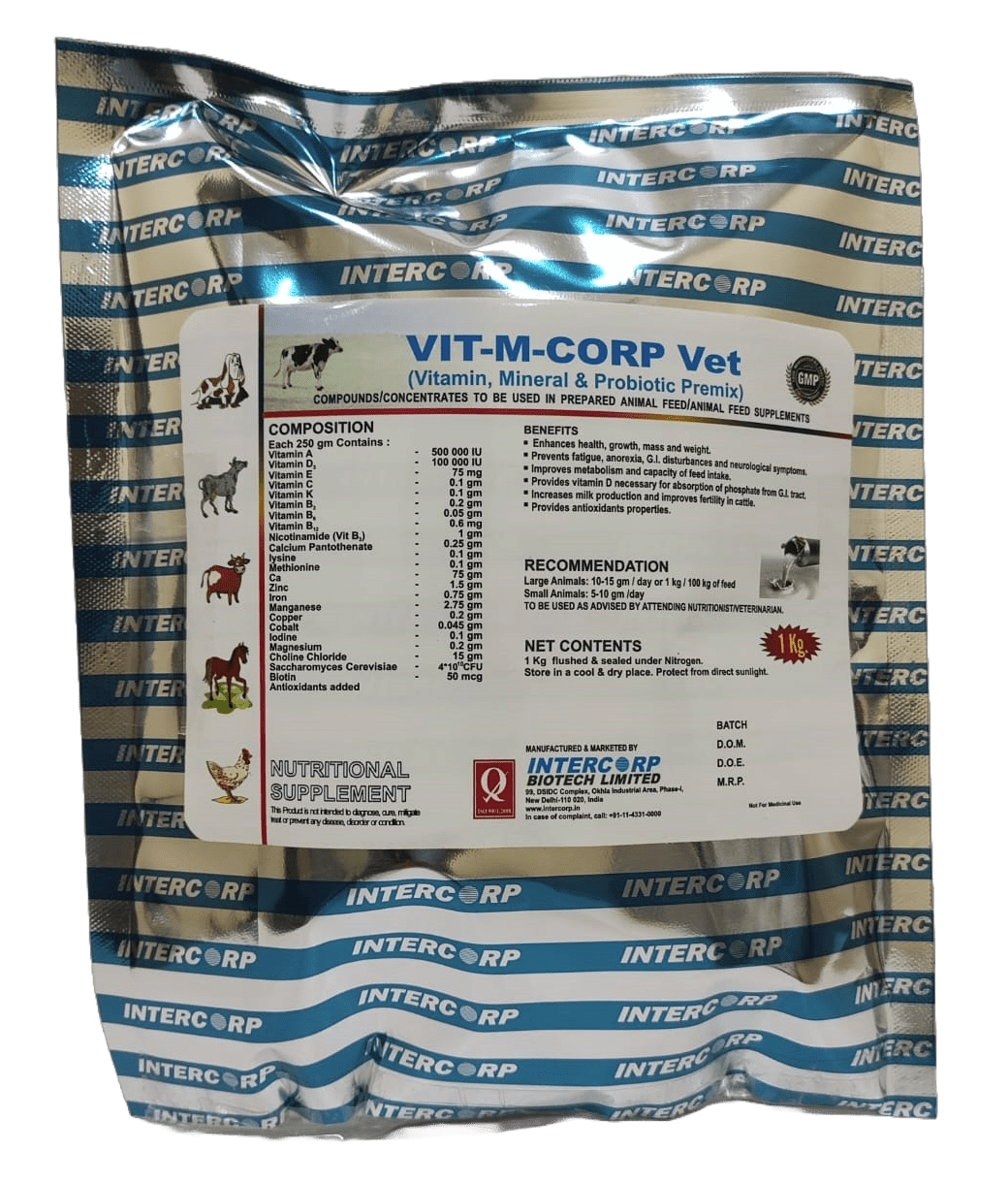

INTERMIX -VIT-M-CORP

High Quality Nutritional Premix

- ADVANTAGES:

- Enhances health, growth, mass, weight and improves metabolism, FCR and capacity of feed intake

- Helps in bone development, maintains osmotic pressure and improves immune response

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Fish and Prawn: 3-5 GM/KG of feed

- Or as advised by nutritionist/veterinarian

- PACKING: 1 KG, 5 KG Pouch, 25 KG (5×5 KG) Bag | Powder.

- For customized specifications and packing – contact us.

INTERMIX – B-ELECTROPLUS

Blend of B Complex, Electro Salts & Energy Boosters

- ADVANTAGES:

- Assists production of homogeneous flocks & reduces early chick mortality

- Adequate supplement during period of stress and digestive upset

- Yeast provides enzymes for phosphorus, fat, protein digestion & inactivate toxins

- Rich source of carbohydrate with other energy boosters

- Choline Chloride protects liver from toxins and fatty changes

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 10 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – BESOL

B Complex Concentrate with Amino Acids Essential Oils & Nutrients

- ADVANTAGES:

- B-complex requirement when feed uptake is reduced due to stress

- Restores normal metabolic functions and feed consumption in off-feed conditions

- Ensures normal growth, egg production, hatchability & gait by correcting riboflavin deficiency

- Checks convulsive movements, head retraction & abnormal excitability caused by pyridoxine deficiency

- Improves haemopoiesis growth and functioning of nerve cells by adequate B12 intake

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Feed Mixing: 3-5 GM/KG of feed

- Pond water: 100 GM in 5 Liter water to make fresh solution for mixing in 1 acre of pond area. Or as advised by nutritionist/veterinarian.

- PACKING: 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – BIOSELVIE

Immunity Booster with Selenium, Vitamins E, Biotin & Antioxidant

- ADVANTAGES:

- Contains strong antioxidants Vitamin E and Selenium

- Improves hatchability and muscular strength

- Improves defense mechanism

- Improves response during post vaccination and viral diseases

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – CALCICORP (VET)

Calcium Health & Milk Tonic

- ADVANTAGES:

- Double strength formula

- Trace minerals improve metabolic, enzymatic & biochemical reactions

- Improves milk production, fertility and conception rate

- Provides antioxidants Selenium & Biotin that improves muscular strength

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – CALCIRICH-DS

(VET)

Calcium Health & Milk Tonic

- ADVANTAGES:

- Improves milk quality and quantity

- Prevents fatigue, anorexia and neurological symptoms

- Improves metabolism and capacity of feed intake

- Meets the requirement of Calcium & Phosphorous during pregnancy, lactation and rapid growth

- Lasts longer – sealed under Nitrogen

- PACKING: 40 LT Dolu | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – CALCIVITE-H

Herbal Supplement with Calcium, Phosphorus Vitamins A,

D3, E & B12

- ADVANTAGES:

- Source of needed nutrients for alleviation of stress

- Vitamin D3 for better absorption and assimilation of Calcium and Phosphorous

- Vitamin B12 for haemopoiesis and toned up neuronal function

- Pre & post calving administration eliminates chances of milk fever

- Asparagus & Leptadenia improve absorption of nutrients and enhance lactogenesis and galactopoiesis

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT, 20 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – DIGESTOCORP (VET)

Liver Tonic Intermix for Cattle Feed Supplementation

- ADVANTAGES:

- Acts as an appetizer, improving feed intake

- Works as a hepatic stimulant to enhance liver functions

- Functions as an immuno-stimulant and protects liver from toxins

- Useful in hepatic damage caused by fungal or other infections

- Supports fatty liver conditions and hepatic dysfunction

- Improves metabolic, enzymatic, and biochemical reactions

- PACKING: 250 ML, 1 LT, 5 LT | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – HIPROVIT-1

Blend of Protein, Iron & Vitamin Concentrate for Growth

- ADVANTAGES:

- Perfect remedy during and post stress episodes

- Improves feed conversion and weight gain in broilers

- Corrects anaemic and morbidity conditions and thereby improves production

- Assures optimum liver function and metabolism

- Ideal during pregnancy, lactation, weakness and debility in canines and other mono gastric animals

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – IMOTECH (STRONG)

Immunity Enhancer Antistressor & Antioxidant

- ADVANTAGES:

- Enhances natural and non-specific immunity

- Enhances phagocytosis and improves defense mechanism

- Protects from production loss and improves muscular strength

- Acts an antioxidant and reduce cell membrane damage

- Improves hatchability in breeders and body weight in broilers

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – LIVDIGEST

Liver Tonic

- ADVANTAGES:

- Perfect combination of metabolic stimulants, antioxidant, vitamins, detoxifiers and highly effective hepatic stimulant herbs

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function, improves immunity

- Silymarin helps in regenerating hepatocytes

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Jar | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – LIVDIGEST STRONG

Superior Liver Tonic for Protection & Performance

- ADVANTAGES:

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function & metabolic processes, improves immunity

- Combats stress, improves feed conversion & growth

- Useful in hepatic damage due to fungal and other hepatotoxins

- Mobilizes fat from liver and protects liver from fatty changes & cirrhosis

- Silymarin helps in regenerating hepatocytes (liver cells)

- PACKING: 1 LT, 5 LT, 20 LT| Liquid.

- For customized specifications and packing – contact us.

INTERMIX – LIVTOP

Liver Tonic for Protection & Performance

- ADVANTAGES:

- Prevents liver disorders and improves liver function

- Mobilizes fat from the liver, prevents fatty liver syndrome

- Source of Vitamin B12 & Folic acid

- Improves defense mechanism, detoxifies liver

- Ensures faster recovery after antibiotic therapy

- Silymarin helps in regenerating hepatocytes (Liver cells)

- Lasts longer – sealed under Nitrogen

- PACKING: 5 LT, 20 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – MYTIBIND EXPO

Broad Spectrum Toxin Binder

- ADVANTAGES:

- Inhibits toxin producing agents and aflatoxins

- Ability to bind multiple mycotoxins and to improve FCR

- Inhibits Salmonella, E. Coli, Clostridium and other bacterial infections

- Improves egg production in Layers and body weight in Broilers

- Improves water quality by reducing pH & improves feed safety

- Reduces hazardous mycotoxins within the gastro-intestinal tract

- Essential oils improve metabolism and enhance immunity

- Choline chloride protects liver from toxins and fatty change

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – NEPHROCORP

Herbal Tonic for Renal Function & Detoxification

- ADVANTAGES:

- Protection against gout, ascites and urinary tract infection

- Useful against infectious microorganism

- Effective diuretic and alkalizer

- Hepatic stimulant with anti-hepatotoxic

- Useful in urinary system disorders

- Improves digestion and provides rejuvenation

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 5 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – RENOTONE

Strong Nephro Health Tonic

- ADVANTAGES:

- Helps in normal functions of kidneys

- Acts as an effective diuretic, alkalizer, and nephroprotective agent

- Works as a hepatic stimulant; useful in urinary system disorders

- Helps in the prevention of gout

- Acts as an immuno-stimulant

- Improves arthritic conditions

- Improves digestion and provides rejuvenation

- PACKING: 1 LT, 5 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – WDS

Concentrate of Vitamins A, C, D & E

- ADVANTAGES:

- Prevents stress arising due to handling infection, medication and environmental changes

- Restores normal health, growth & production

- Improves body resistance immunity

- Check retarded growth, low hatchability & egg production

- Provides essential Amino Acids -Lysine & Methionine

- Lasts longer – sealed under Nitrogen

- PACKING: 500 ML, 1 LT Bottle | Liquid.

- For customized specifications and packing – contact us.

The Need

Nutrient Deficiencies in Natural Feed Ingredients: plant-based feed lacks critical nutrients like vitamins, fatty acids, and minerals necessary for growth and disease resistance. Journal of Food and Beverages, Feed Navigator

Improving Feed Efficiency & Productivity: Poultry: additives improve growth rates, survival, and resilience to environmental stress. Feed Navigator

Combating Mycotoxins & Other Feed Contaminants: mycotoxins in feed reduce performance and lead to health issues. Feed Strategy

Reducing Antibiotic Use & Promoting Sustainable Farming: probiotics and herbal additives reduce reliance on antibiotics, improving gut health, critical for sustainable farming. Lark Engineering

Supporting Economic Growth: aquaculture is a significant contributor to rural economy. Better productivity helps farmers meet demand for fish, thus improving livelihoods.

Advantages

- Longer lasting premix, due to reduced reactivity of nutrients from environment exposure – from cutting-edge Microencapsulation Technology.

- Controlled release of nutrients in feed – from cutting-edge Microencapsulation Technology.

- Happy consumers due to assured nutrient delivery – from cutting-edge Microencapsulation Technology.

- Cost effective nutrient fortification – no investment in new equipment.

- Assured & consistent quality – COA available on request.

- Made from safe materials – SDS available on request.

- Brand loyalty & trusting consumers.

Process

Through Pond conditioning, mixing with feed, or as advised by veterinarians.

INTERMIX – AMO-GO (AQUA)

Water Miscible Vitamin A Concentrate for Aquaculture Feed Supplement

- ADVANTAGES:

- Nitrifying and Denitrifying bacteria reduce ammonia and nitrate levels

- Enhances the growth of Phytoplankton and Zooplankton

- Reduces bottom sludge and stabilizes the water colour

- Strains are adaptable to different pH and salinity conditions

- Reduces organic load and pollution in the pond through mineralization process

- Increases DO level

- Reduces frequency of water change

- Reduces mortality rate of prawn, shrimp and fish

- Reduces bacterial toxins in pond and improves defense mechanism

- Improves appetite, digestion, feed intake & body weight

- Prebiotics MOS & FOS promote beneficial bacterial growth in the gastrointestinal tract

- PACKING: 1 KG, 25 KG | Powder.

- For customized specifications and packing – contact us.

INTERMIX – BLUE CATCH

Multi-Vitamin & Mineral Supplements for Growth

- ADVANTAGES:

- Improves growth & weight

- Protects from vitamin & mineral deficiencies

- Ensures better survival rate of shrimp/ fish

- Helps in molting and shell formation

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

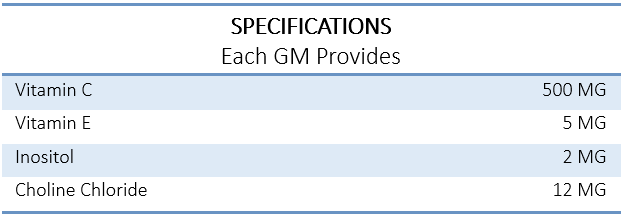

INTERMIX – BLUETONE – C PLUS

Blend of Vitamin C with Synergetic Ingredients Supplement for Aquaculture

- ADVANTAGES:

- Prevents deficiency of essential dietary feed supplement Vitamin C for shrimp, prawn and fish

- Vitamin C synthesizes collagen. Collagen is a connective tissue that holds muscles, bones and other tissues together as well as heals wounds

- Vitamin E together with Vitamin C work as antioxidant, neutralize free radicals from the body

- Vitamin C enhances immune response with survival rate

- Vitamin C helps in absorption of iron from plant based foods

- Vitamin C regulates the molt phase, helps in quick formation of exoskeleton in shrimps

- Vitamin C reduces negative effects of water temperature fluctuations

- Vitamin C prevents deformities of the skeleton & promotes growth rate

- Vitamin C reduces handling, environmental, osmotic, transportation and pathogenic stress of fishes and shrimps

- Vitamin C helps in reproduction & reduces mortality in early stages of fishes & shrimps

- Choline ensures better appetite, FCR, maintenance of cell structure and nerve impulses

- Inositol improves cell membrane permeability, skeletal structural, heart and brain tissue, liver and bone marrow cells & synthesis of RNA

- PACKING: 1 KG | Powder.

- For customized specifications and packing – contact us.

INTERMIX – ECOKILL

Water Sanitizer

- ADVANTAGES:

- Prevents bacteria, virus, and fungi

- Prevents re-contamination upto 72 hours

- Does not alter taste or pH of water

- Helps in faster sedimentation of physical impurities

- Lasts longer – sealed under Nitrogen

- PACKING: 100 GM, 200 GM, 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – LIVDIGEST

Water Miscible Liver Tonic for Protection & Performance Supplementation

- ADVANTAGES:

- Perfect combination of metabolic stimulants, antioxidants, vitamins, detoxifiers, and highly effective hepatic stimulants.

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function

- Improves metabolic processes

- Combats stress and improves FCR

- Useful in hepatic damage due to fungal and other hepatotoxins

- Mobilizes fat from liver and protects liver from fatty changes & cirrhosis

- Improves immunity, Egg production and body weight

- Supports nephrotic tissue functions

- PACKING: 1 KG Pouch, 25 KG (5x5KG) | Powder.

- For customized specifications and packing – contact us.

INTERMIX – PROBEE WATER MISCIBLE

Probiotics & Enzyme Premix

- ADVANTAGES:

- Lactobacillus competes with harmful coliforms and pathogenic microbes on the intestinal surface, resulting in competitive exclusion

- Helps in production of lactic acid that reduces gut pH, lowering pathogen levels and reducing E. coli, Salmonella, and Staphylococcus count

- Reduces early chick mortality; promotes better weight gain and egg production

- Reduces stress during vaccination and de-beaking

- Provides enzymes for Phosphorus, Fat, and Protein digestion

- Enhances metabolism of Carbohydrates

- Yeast ferments Carbohydrates and inactivates toxins

- Acts as a source of Vitamin B-Complex and improves feed conversion

- PACKING: 100 GM, 1 KG, 5 KG, 25 KG | Powder.

- For customized specifications and packing – contact us.

INTERMIX – PROBEE IMPROVED

Probiotics for Growth & Health –Feed Mixing

- ADVANTAGES:

- Protects the aquatic animals from bacterial pathogens

- Ensures better absorption of nutrients

- Improves health and weight

- Improves immunity, reduce disease incidence and mortality

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX -VIT-M-CORP

High Quality Nutritional Premix

- ADVANTAGES:

- Enhances health, growth, mass, weight and improves metabolism, FCR and capacity of feed intake

- Helps in bone development, maintains osmotic pressure and improves immune response

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Fish and Prawn: 3-5 GM/KG of feed

- Or as advised by nutritionist/veterinarian

- PACKING: 1 KG, 5 KG Pouch, 25 KG (5×5 KG) Bag | Powder.

- For customized specifications and packing – contact us.

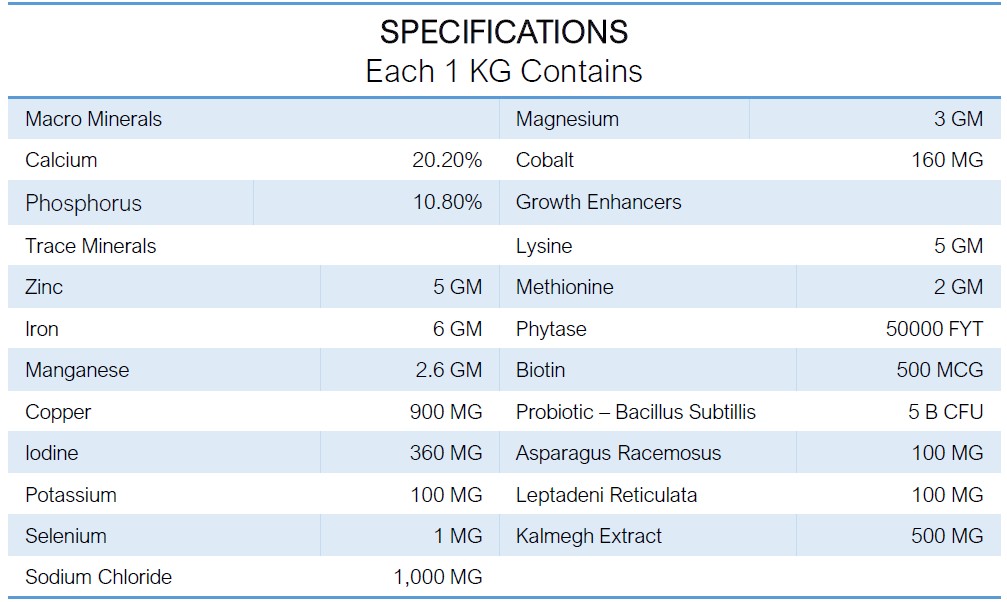

INTERMIX – ZMIN-PLUS

Vitamin & Mineral Mixture with Growth Enhancers

- ADVANTAGES:

- Improves skeleton and muscular strength

- Ensure strong shell & prevent body cramps

- Regulates osmoregulation

- Develops and maintains the planktons

- Lasts longer – sealed under Nitrogen

- PACKING: 1 KG Jar | Powder.

- For customized specifications and packing – contact us.

INTERMIX – B-ELECTROPLUS

Blend of B Complex, Electro Salts & Energy Boosters

- ADVANTAGES:

- Assists production of homogeneous flocks & reduces early chick mortality

- Adequate supplement during period of stress and digestive upset

- Yeast provides enzymes for phosphorus, fat, protein digestion & inactivate toxins

- Rich source of carbohydrate with other energy boosters

- Choline Chloride protects liver from toxins and fatty changes

- Lasts longer – sealed under Nitrogen

- PACKING: 1 LT Bottle, 10 LT Can | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – LIVDIGEST

Liver Tonic

- ADVANTAGES:

- Perfect combination of metabolic stimulants, antioxidant, vitamin, detoxifiers and highly effective hepatic stimulant herbs

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function, improves immunity

- Silymarin helps in regenerating hepatocytes

- Lasts longer – sealed under Nitrogen

- ADMINISTRATION:

- Feed Mixing: 10-15 ML/KG of feed

- Pond Water: 2 Liter/Acre of pond water

- Or as advised by nutritionist/veterinarian

- PACKING: 1 LT Bottle, 5 LT Jar | Liquid.

- For customized specifications and packing – contact us.

INTERMIX – LIVDIGEST STRONG

Superior Liver Tonic for Protection & Performance

- ADVANTAGES:

- Hepatic stimulant with anti-hepatotoxic activity

- Supports liver function & metabolic processes, improves immunity

- Combats stress, improves feed conversion & growth

- Useful in hepatic damage due to fungal and other hepatotoxins

- Mobilizes fat from liver and protects liver from fatty changes & cirrhosis

- Silymarin helps in regenerating hepatocytes (liver cells)

- PACKING: 1 LT, 5 LT, 20 LT| Liquid.

- For customized specifications and packing – contact us.

What Makes Us Different?

Cutting Edge Technology

Microencapsulation of nutrients for assured nutrient delivery

Longer

Lasting

Product in Nitrogen makes nutrients last longer

Flexibility For Customers

Make customizable products as per customer’s needs

Global Standards

As per WHO-FAO, FSSAI recommendations

Safe Materials

Material Safety Data (MSD) for usage, storage & carriage

100% Vegetarian

No animal source material used

Cost Effective

Economical fortification cost

On-time Delivery

Proactive Customer Support

Assured Quality

Consistent product quality (COA)

Get Customized Premixes Tailormade to your Requirements

GET IN TOUCH FOR ALL YOUR FORTIFICATION NEEDS